Explore the design, operation, applications, and limitations of wound rotor induction motors in our comprehensive guide.

Introduction to Wound Rotor Induction Motors

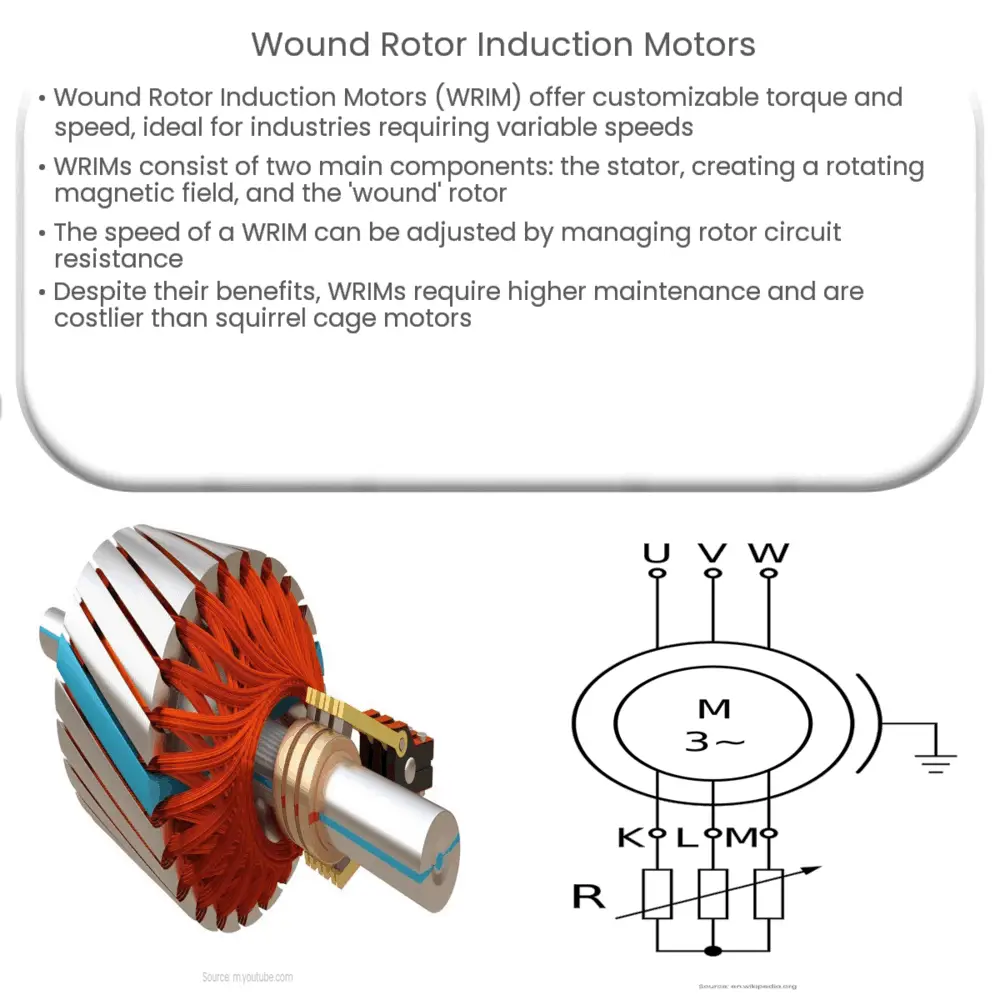

When it comes to the world of electric motors, wound rotor induction motors (WRIM) occupy a significant position. Offering customizable torque and speed characteristics, these motors exhibit a broad range of applications in industries where variable speed is crucial.

At the heart of WRIM is its distinct construction, which deviates from that of traditional squirrel cage rotor motors. Understanding the design and operation of WRIM is the key to leveraging its benefits and ensuring its optimal use.

Design and Construction

Like all induction motors, a wound rotor induction motor comprises two main components: the stator and the rotor. The stator houses the primary winding where an alternating current (AC) is applied to create a rotating magnetic field. In the case of a WRIM, the rotor, as the name suggests, is ‘wound’ and looks very similar to the stator.

- The stator consists of a set of insulated windings placed in the motor’s outer frame. Usually, these windings are made of copper or aluminum bars, and when energized, they produce an electromagnetic field.

- The rotor of a WRIM is wound like a transformer secondary. Each of these windings is connected to slip rings, which in turn are connected to external resistors via brushes.

Operation Principle

The operational principle of a wound rotor induction motor relies heavily on Faraday’s Law of electromagnetic induction. When an AC supply is given to the stator, it generates a rotating magnetic field. This rotating magnetic field induces a current in the rotor, creating its own magnetic field. The interaction between the two fields is what generates the torque, causing the rotor to turn.

The speed of the rotor is always less than the speed of the stator’s magnetic field – a difference known as ‘slip’. The speed of a WRIM can be controlled by managing the amount of resistance in the rotor circuit. This is achieved by adjusting the external resistors connected to the slip rings. The more the resistance, the greater the slip, and hence, slower is the speed of the motor.

Advantages of Wound Rotor Induction Motors

Wound rotor induction motors provide several benefits, especially in specific industrial applications:

- High starting torque: WRIMs are capable of producing a high starting torque at a low starting current, making them ideal for heavy start applications.

- Speed control: The unique design of WRIM allows for variable speed operation, which is a significant advantage in industries where speed control is essential.

Despite these benefits, understanding the applications and limitations of WRIM is essential for its effective utilization, which we will delve into in the next section.

Applications of Wound Rotor Induction Motors

The versatility and robustness of wound rotor induction motors have made them the go-to solution for various industrial operations. These include:

- Conveyors: WRIMs are frequently used in belt conveyors, where variable speed and high starting torque are critical requirements.

- Hoists and lifts: The high starting torque and speed control attributes make these motors ideal for lifts and hoist mechanisms.

- Pumps and compressors: Wound rotor motors are often employed in large pump and compressor systems where start-up load is heavy and variable speed is necessary.

- Grinding mills: In grinding mills, these motors provide the necessary high torque required for the initial start-up.

Limitations and Considerations

Despite the many advantages and applications, WRIMs do come with certain limitations that users must be aware of:

- Due to the slip rings and brushes in the rotor circuit, maintenance requirements are comparatively higher.

- The complex design of WRIM leads to increased costs compared to squirrel cage induction motors.

- The presence of brushes and slip rings in WRIM can also lead to potential safety hazards, particularly in explosive or flammable environments.

Conclusion

Wound rotor induction motors play a crucial role in numerous industrial applications thanks to their unique design and operational features. Their high starting torque and variable speed capabilities make them an excellent choice for applications requiring these specific characteristics. However, like any technology, understanding its strengths and limitations is fundamental for making the most of its potential.

While WRIMs require more maintenance and are costlier than their squirrel cage counterparts, the versatility they offer often outweighs these drawbacks, particularly in heavy-start and variable speed scenarios. As technology continues to evolve, so will the design and efficiency of wound rotor induction motors, promising an even wider array of applications in the future.

Ultimately, the choice between a wound rotor induction motor and other types of motors should be made based on the specific needs and circumstances of each application.