Explore the world of Variable Reluctance Stepper Motors – their working principle, features, applications, and future potential.

Introduction to Variable Reluctance Stepper Motors

The realm of electric motors is wide and varied, with each type having its own unique features and applications. One such type of motor is the Variable Reluctance (VR) Stepper Motor. This type of stepper motor has its own unique characteristics that distinguish it from others.

What is a Variable Reluctance Stepper Motor?

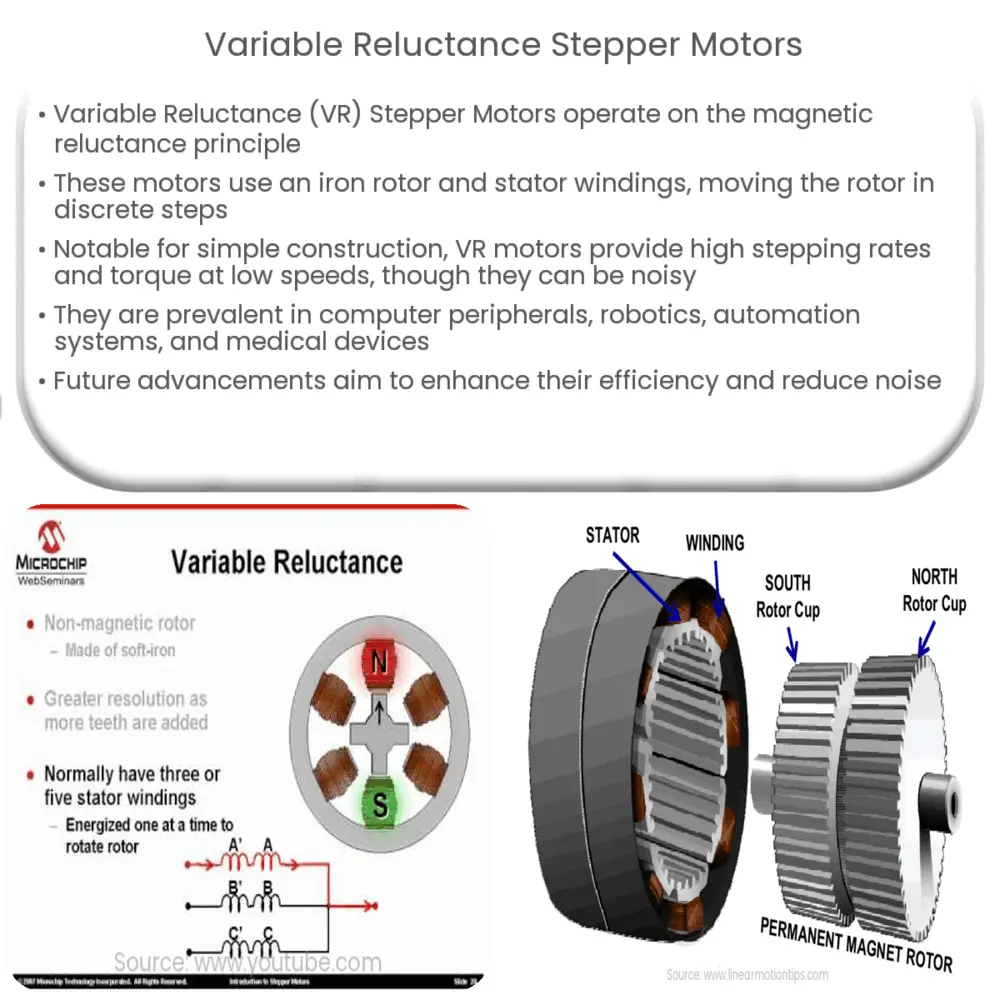

A Variable Reluctance Stepper Motor is a type of electric motor that operates based on the principle of magnetic reluctance. This motor is built with an iron rotor and multiple stator windings. The windings are magnetized in a specific sequence, causing the rotor to move in discrete steps. This is the basis of the stepper motor’s name and operation.

Working Principle of VR Stepper Motors

The operation of a VR stepper motor is governed by the principle of magnetic reluctance, which is the resistance of a magnetic circuit to magnetic flux. The rotor, which is an iron piece, tends to align itself along the path of least magnetic reluctance, i.e., it tries to position itself in such a way that it faces more of the magnetized stator pole and less of the air gap.

As different stator windings are sequentially energized, the path of least reluctance changes, causing the rotor to move in steps to continually align itself with the lowest reluctance path. This step-wise movement allows for precise control of motor rotation, which makes VR stepper motors suitable for various applications requiring precision and control.

Features of Variable Reluctance Stepper Motors

-

VR stepper motors are known for their simple construction. The rotor is usually made from soft iron and is not wound, which makes it lighter and potentially faster than other types of stepper motors.

-

They offer high stepping rates and good torque at low speeds. However, at higher speeds, the performance might be less satisfactory due to resonance issues.

-

VR motors are considered to be robust and reliable, which makes them suitable for environments where the motor could be subjected to harsh conditions.

-

One of the major drawbacks of a VR stepper motor is that it tends to be noisier compared to other types of stepper motors. This is because the rotor is not as well-damped, leading to a higher degree of mechanical vibration.

Applications of Variable Reluctance Stepper Motors

Due to their unique characteristics, VR stepper motors are used in a multitude of applications where precision and control are paramount. Some of these applications are:

-

Computer Peripherals: VR stepper motors are extensively used in computer peripherals like printers and disk drives, where they control the precise movement of parts.

-

Robotics: Robots often need precise control of their movements. VR stepper motors, with their precise step-wise movement, are a popular choice for many robotics applications.

-

Automation Systems: Automated assembly lines and machines often use VR stepper motors to accurately control their operations.

-

Medical Devices: VR stepper motors are used in various medical devices where precision is critical, such as in medical imaging devices and automated drug delivery systems.

The Future of Variable Reluctance Stepper Motors

While Variable Reluctance Stepper Motors have been around for some time, they continue to hold significant potential for the future. Advancements in material science, control algorithms, and electronic driver technology could lead to improvements in their performance and efficiency. Particularly, research is ongoing on developing more effective damping techniques to reduce the noise and vibration levels of these motors, which could further broaden their application range.

Conclusion

In conclusion, the Variable Reluctance Stepper Motor is a simple yet versatile motor that operates based on the principle of magnetic reluctance. Its ability to provide precise control makes it a valuable component in numerous applications, from computer peripherals to advanced robotics. While it has certain limitations, ongoing technological advancements hold promise for enhancing the performance and capabilities of VR stepper motors, making them a key component in the world of electric motors for years to come.