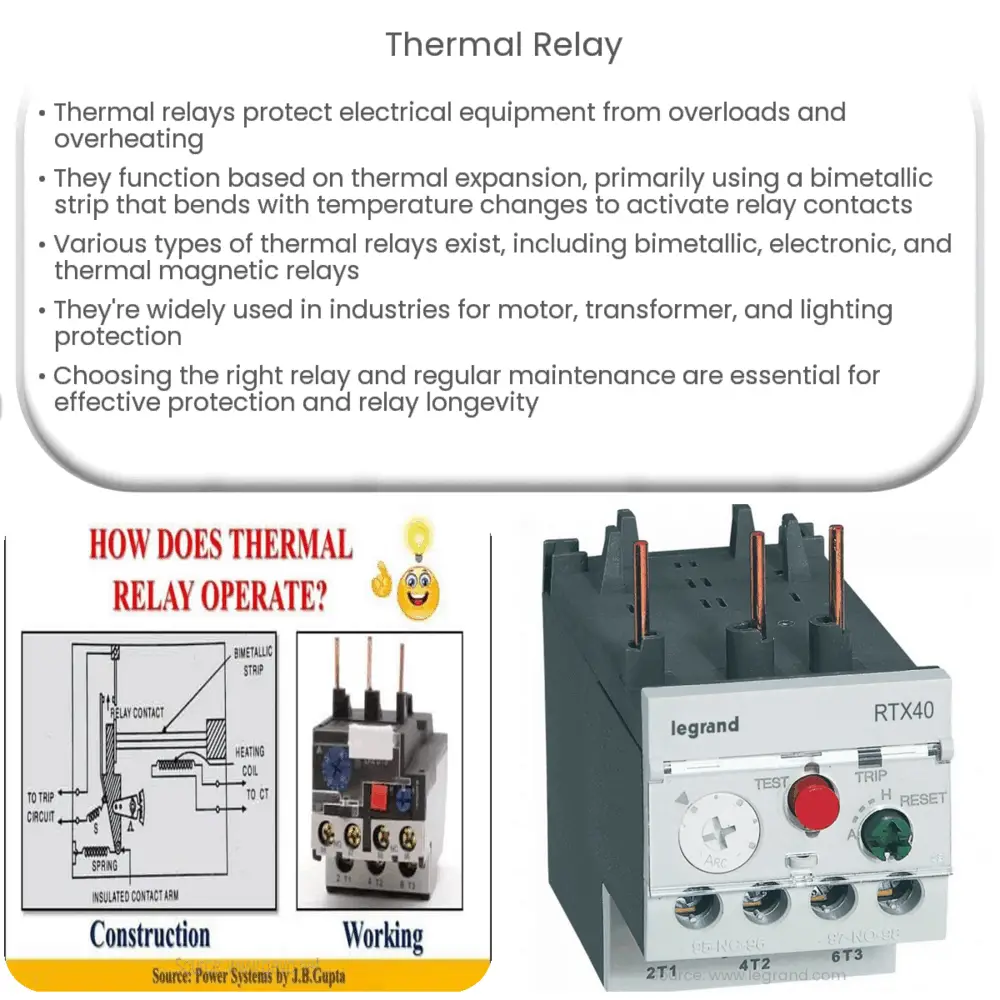

A thermal relay is an electromechanical device that detects temperature changes in electrical circuits, protecting equipment from overload and overheating.

Understanding Thermal Relays: An Essential Guide

Thermal relays are critical components in electrical systems, designed to protect motors and other electrical equipment from damage caused by overloads and overheating. In this article, we will delve into the basics of thermal relays, their working principle, and their applications in various industries.

What is a Thermal Relay?

A thermal relay, also known as a thermal overload relay, is an electromechanical device that senses abnormal temperature increases in electrical circuits. It responds to these temperature changes by opening or closing contacts, which in turn interrupts the power supply to the equipment, preventing damage from overheating or overload conditions.

How Do Thermal Relays Work?

Thermal relays work on the principle of thermal expansion. The core component of a thermal relay is a bimetallic strip, which is made up of two different metals with different rates of thermal expansion, bonded together. As the temperature in the electrical circuit increases, the two metals expand at different rates, causing the bimetallic strip to bend or deform. This deformation triggers the relay’s contacts to open or close, depending on the application.

Some thermal relays also use a heating element in conjunction with the bimetallic strip. When an overload condition occurs, the heating element generates heat, which is then transferred to the bimetallic strip, causing it to bend and activate the relay contacts. This design allows for greater sensitivity and accuracy in detecting temperature changes.

Types of Thermal Relays

There are several types of thermal relays, including:

- Bimetallic Thermal Relays: These relays use a bimetallic strip to detect temperature changes, as discussed earlier. They are simple, reliable, and cost-effective, making them the most commonly used type of thermal relay.

- Electronic Thermal Relays: These relays use electronic components, such as thermistors or temperature sensors, to detect temperature changes. They offer higher accuracy and more advanced features, such as digital displays and communication capabilities, but are typically more expensive than bimetallic thermal relays.

- Thermal Magnetic Relays: These relays combine the principles of both thermal and magnetic relays. They provide protection against both overloads and short circuits, making them suitable for applications where both types of protection are required.

Applications of Thermal Relays

Thermal relays are widely used across various industries and applications to safeguard electrical equipment. Some common applications include:

- Motor protection: Preventing motor damage caused by overloads, overheating, or phase failures.

- Transformer protection: Detecting and preventing overheating in transformers, which can lead to insulation breakdown and failure.

- Lighting protection: Protecting lighting systems from damage caused by overloads or short circuits.

Selecting the Right Thermal Relay

Choosing the correct thermal relay for your application is crucial to ensure effective protection and reliable operation. Consider the following factors when selecting a thermal relay:

- Load type: The nature of the electrical load, such as whether it is resistive, inductive, or capacitive, affects the relay’s performance and sensitivity. Ensure that the chosen relay is compatible with your specific load type.

- Current rating: The thermal relay’s current rating should match or exceed the maximum current that the protected equipment is designed to handle. This ensures that the relay can adequately protect the equipment without premature activation.

- Temperature range: Select a thermal relay with a temperature range that covers the expected operating conditions of your equipment. This ensures accurate temperature sensing and reliable protection.

- Response time: The relay’s response time should be compatible with the thermal characteristics of the protected equipment. A faster response time is preferred for equipment that is more sensitive to temperature changes.

- Additional features: Consider any additional features that may be beneficial for your application, such as adjustable settings, reset options, or communication capabilities.

Maintenance and Troubleshooting

To ensure the proper functioning and longevity of thermal relays, regular maintenance and troubleshooting are essential. Here are some recommendations:

- Visual inspection: Regularly inspect the relay for signs of wear, damage, or corrosion. Replace any damaged components as needed.

- Cleaning: Keep the relay and its surrounding area clean and free of dust, debris, and moisture. This helps maintain proper heat dissipation and prevent false activations.

- Testing: Periodically test the relay’s functionality by simulating an overload or overheating condition. This ensures that the relay is working correctly and can respond to actual events.

- Calibration: Over time, the relay’s calibration may drift, affecting its accuracy and performance. Regularly recalibrate the relay, as specified by the manufacturer, to maintain optimal performance.

Conclusion

Thermal relays play a critical role in protecting electrical equipment from damage caused by overloads and overheating. By understanding their working principles, types, and applications, you can select the right relay for your needs and ensure the safety and longevity of your electrical systems. Regular maintenance and troubleshooting can further enhance the reliability and effectiveness of your thermal relay, ensuring optimal performance and protection for your equipment.