Silver solder is a strong, corrosion-resistant alloy used for joining metals in electronics, jewelry, plumbing, and automotive industries.

Silver Solder: An Essential Guide

Introduction

Silver solder, also known as silver brazing alloy, is a vital component in the world of metalworking and electronics. It is prized for its exceptional strength, corrosion resistance, and electrical conductivity. This guide will provide an in-depth overview of silver solder, its properties, and applications, as well as essential tips for using it effectively.

What is Silver Solder?

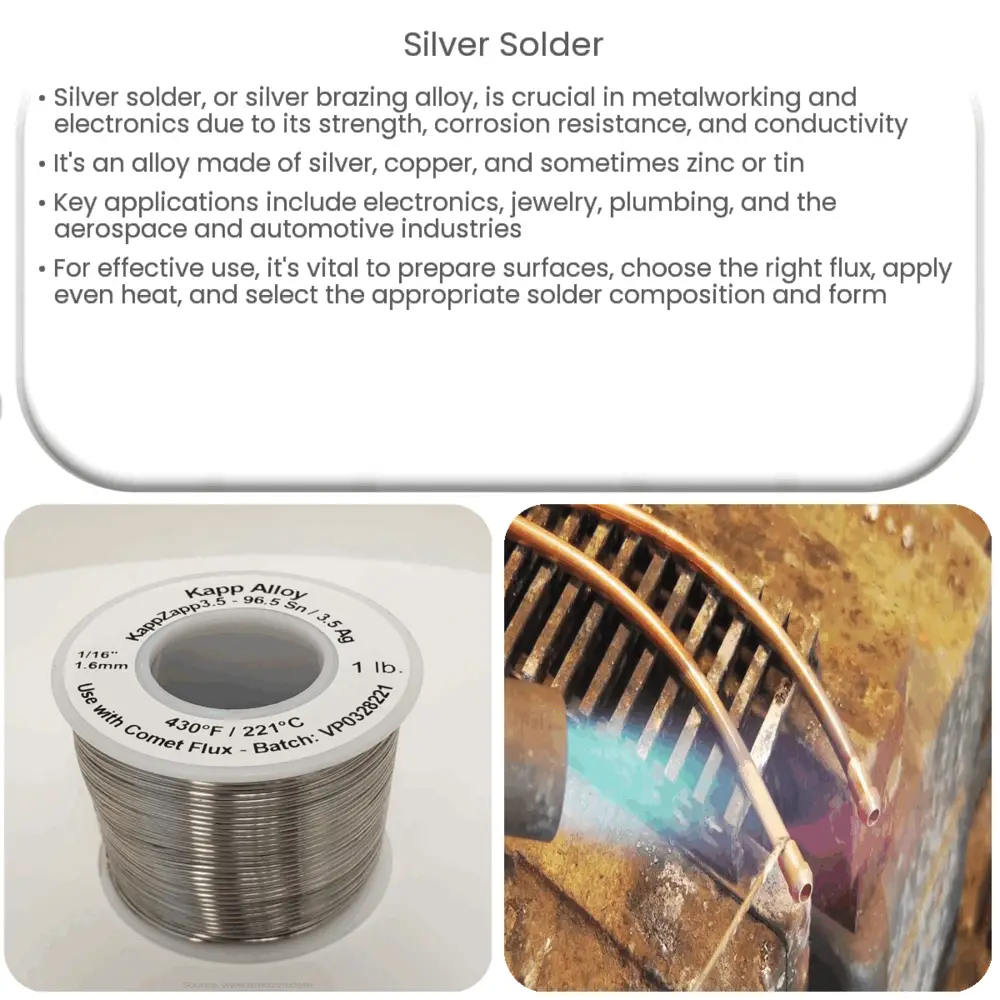

Silver solder is a type of filler metal used for joining or brazing two metal pieces together. It is an alloy, typically composed of silver, copper, and other metals like zinc or tin. The specific composition of silver solder determines its melting temperature and mechanical properties. It is available in various forms, such as wire, paste, or pre-formed shapes to suit different applications.

Properties of Silver Solder

There are several key properties that make silver solder an ideal choice for a wide range of applications:

- Strength: Silver solder is known for its excellent tensile strength, making it ideal for joining metals in high-stress environments or for applications requiring a robust bond.

- Corrosion Resistance: The addition of silver to the alloy provides improved corrosion resistance compared to other solder types, making it suitable for applications exposed to harsh environments or corrosive substances.

- Electrical Conductivity: Silver solder has exceptional electrical conductivity, which makes it an excellent choice for electronic applications where a reliable and efficient connection is necessary.

- Thermal Conductivity: Its high thermal conductivity ensures efficient heat distribution and dissipation, which is crucial for applications where thermal management is a concern.

Applications of Silver Solder

Due to its desirable properties, silver solder is used in a wide array of industries and applications. Some of the most common uses include:

- Electronics: Silver solder is widely used for creating reliable electrical connections in electronic devices, such as circuit boards, sensors, and connectors.

- Jewelry: In the jewelry industry, silver solder is used for joining precious metal components, such as gold, silver, and platinum, without compromising their appearance or integrity.

- Plumbing: Silver solder is often used in plumbing applications for joining copper pipes and fittings, ensuring a strong, leak-free connection.

- Aerospace and Automotive: Due to its strength and corrosion resistance, silver solder is frequently used in the aerospace and automotive industries for joining components exposed to high-stress environments or corrosive substances.

In the next section, we will delve deeper into the process of using silver solder, including essential tips for achieving a strong and reliable bond, and how to select the appropriate type of silver solder for your specific application.

Using Silver Solder: Essential Tips

To ensure a strong and reliable bond when using silver solder, follow these essential tips:

- Surface Preparation: Clean the surfaces to be joined thoroughly, removing any dirt, grease, or oxidation. This will promote better wetting of the solder and a stronger bond.

- Flux Selection: Choose an appropriate flux for your application. Flux is a chemical compound that helps the solder flow and bond to the metals being joined. It also prevents oxidation during the soldering process.

- Heating: Heat the joint evenly using a torch or soldering iron. Ensure that both parts being joined reach the solder’s melting temperature to allow proper flow and bonding.

- Applying Solder: Once the joint has reached the appropriate temperature, apply the silver solder. It should flow smoothly and evenly across the joint.

- Cooling and Cleaning: Allow the joint to cool naturally without disturbing it. Once cooled, remove any excess flux residue using a suitable solvent or warm water.

- Inspection: Inspect the soldered joint for proper wetting, full coverage, and a smooth, shiny appearance. A well-soldered joint should be strong, reliable, and free of defects.

Selecting the Right Silver Solder

There are several factors to consider when selecting the right silver solder for your specific application:

- Composition: Silver solders vary in their silver, copper, and other metal content, which affects their melting temperature and mechanical properties. Choose a solder with the right composition to suit your specific needs.

- Melting Temperature: Consider the melting temperature of the solder and the metals being joined. A solder with a melting temperature lower than the metals being joined will prevent damage to the base material, while a higher melting temperature can provide a stronger bond.

- Form: Silver solder is available in various forms, such as wire, paste, or pre-formed shapes. Select a form that suits your application and soldering method.

- Compatibility: Ensure the solder is compatible with the metals being joined and any other materials involved in the process, such as flux or protective coatings.

Conclusion

Silver solder is a versatile and essential component in numerous industries and applications, thanks to its exceptional strength, corrosion resistance, and electrical conductivity. By understanding its properties and applications, as well as following best practices for using silver solder, you can achieve strong and reliable bonds for a wide range of metalworking and electronic projects. Always consider factors like composition, melting temperature, and compatibility when selecting the right silver solder for your needs, and remember to prepare surfaces, use appropriate flux, and heat evenly for optimal results.