Resistive gas sensors are affordable, versatile devices that detect target gases by altering electrical resistance, used in air quality monitoring, industrial safety, and automotive emissions.

Resistive Gas Sensors: An Introduction and Overview

What are Resistive Gas Sensors?

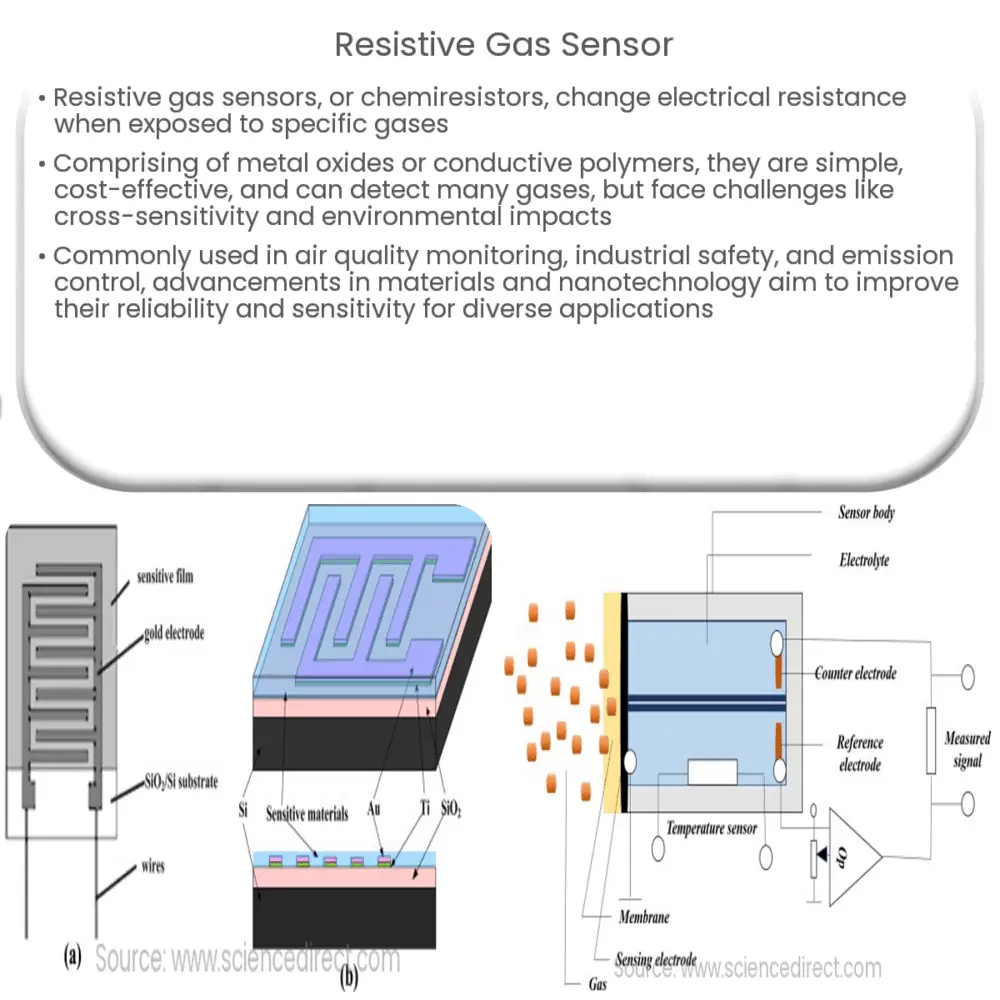

Resistive gas sensors, also known as chemiresistors, are a type of gas detection device that function by altering their electrical resistance in the presence of specific target gases. They are widely used in a variety of applications, such as environmental monitoring, industrial safety, and air quality control. These sensors are known for their simplicity, low cost, and ability to detect a wide range of gases, making them a popular choice in many sectors.

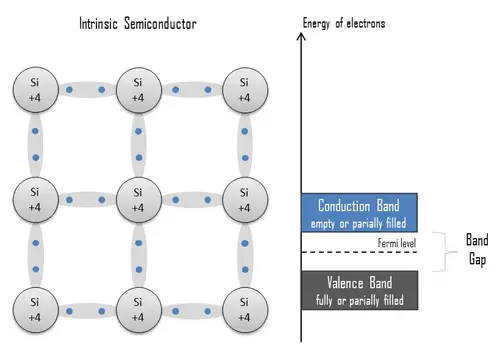

Working Principle of Resistive Gas Sensors

Resistive gas sensors are comprised of a sensing element, typically made of metal oxides or conductive polymers, which undergoes a resistance change when exposed to a target gas. The interaction between the sensing material and the gas molecules causes a change in the material’s electrical properties, which can be measured and correlated to the concentration of the target gas.

There are two main types of resistive gas sensors: n-type and p-type. In n-type sensors, the resistance decreases in the presence of a reducing gas (e.g., carbon monoxide or hydrogen), while in p-type sensors, the resistance increases in the presence of an oxidizing gas (e.g., ozone or nitrogen dioxide). The choice of sensing material and its specific properties determine the sensor’s selectivity and sensitivity to various gases.

Advantages and Disadvantages of Resistive Gas Sensors

Resistive gas sensors offer several advantages over other gas detection technologies, such as electrochemical or infrared sensors. Some of these benefits include:

- Low cost: Resistive gas sensors are typically more affordable than other sensing technologies, making them accessible for a wide range of applications.

- Simple construction: These sensors have a straightforward design, which allows for easy fabrication and integration into existing systems.

- Wide range of detectable gases: With the right choice of sensing material, resistive gas sensors can be tailored to detect a broad array of target gases.

However, resistive gas sensors also have some limitations, including:

- Reduced selectivity: The sensitivity of these sensors to multiple gases can result in cross-sensitivity issues, leading to false readings or reduced accuracy.

- Long response and recovery times: Depending on the sensing material, resistive gas sensors may require more time to respond to and recover from target gas exposure compared to other sensor technologies.

- Sensitivity to environmental conditions: Factors such as temperature and humidity can impact the performance of resistive gas sensors, necessitating careful calibration and compensation measures.

Applications of Resistive Gas Sensors

Resistive gas sensors find use in various applications across different industries. Some common examples include:

- Air quality monitoring: These sensors can detect harmful gases and pollutants in the environment, ensuring safe and healthy living conditions.

- Industrial safety: In industries dealing with hazardous chemicals, resistive gas sensors are employed to detect gas leaks and maintain safe working conditions.

- Automotive emission control: The automotive industry uses resistive gas sensors to monitor and control exhaust emissions, thereby reducing environmental pollution.

Materials Used in Resistive Gas Sensors

Various materials can be employed as the sensing element in resistive gas sensors, each offering different properties and detection capabilities. Some of the most commonly used materials include:

- Metal oxides: Metal oxide semiconductors (MOS) are widely used in resistive gas sensors due to their high sensitivity and selectivity to different gases. Examples of metal oxides used in gas sensors are tin dioxide (SnO2), zinc oxide (ZnO), and tungsten trioxide (WO3).

- Conductive polymers: These are organic materials that exhibit a change in resistance upon exposure to specific gases. Conductive polymers, such as polyaniline (PANI) and polypyrrole (PPy), offer advantages like low cost and good sensitivity to various gases.

- Carbon-based materials: Carbon nanotubes (CNTs) and graphene are emerging as promising materials for resistive gas sensors due to their high surface area and excellent electrical properties. These materials have shown potential for enhanced sensitivity and selectivity in gas sensing applications.

Improving Resistive Gas Sensor Performance

Researchers are continuously exploring methods to enhance the performance of resistive gas sensors in terms of sensitivity, selectivity, response time, and recovery time. Some approaches include:

- Nanostructuring: By using nanoscale materials, such as nanoparticles or nanowires, the sensor’s surface area can be significantly increased, leading to improved sensitivity and faster response times.

- Material doping: Adding dopants or modifying the sensing material composition can result in better selectivity and sensitivity to target gases.

- Hybrid materials: Combining different materials, such as metal oxides with carbon-based materials, can offer synergistic effects that enhance the sensor’s performance.

- Temperature control: Optimizing the operating temperature of resistive gas sensors can lead to improved sensitivity and selectivity, as well as faster response and recovery times.

Future Prospects and Challenges

Resistive gas sensors continue to play a critical role in various applications, and ongoing research efforts aim to further improve their performance and expand their capabilities. The emergence of new materials, such as 2D materials and advanced nanostructures, promises to revolutionize the field of gas sensing. Moreover, the integration of resistive gas sensors with advanced electronics and wireless communication technologies can enable the development of smart sensing systems and the Internet of Things (IoT) applications.

However, challenges remain in addressing issues related to cross-sensitivity, long-term stability, and environmental influences. Developing sensors with higher selectivity, improved stability, and robustness against environmental factors will be crucial for unlocking the full potential of resistive gas sensors in various applications.

Conclusion

Resistive gas sensors are versatile and cost-effective solutions for detecting a wide range of gases in diverse applications. By understanding their working principles, advantages, disadvantages, and ongoing research, one can better appreciate their role in maintaining a safe and healthy environment. As advancements in materials science and nanotechnology continue to progress, resistive gas sensors are expected to become even more reliable, sensitive, and selective, making them invaluable tools in various industries and applications.