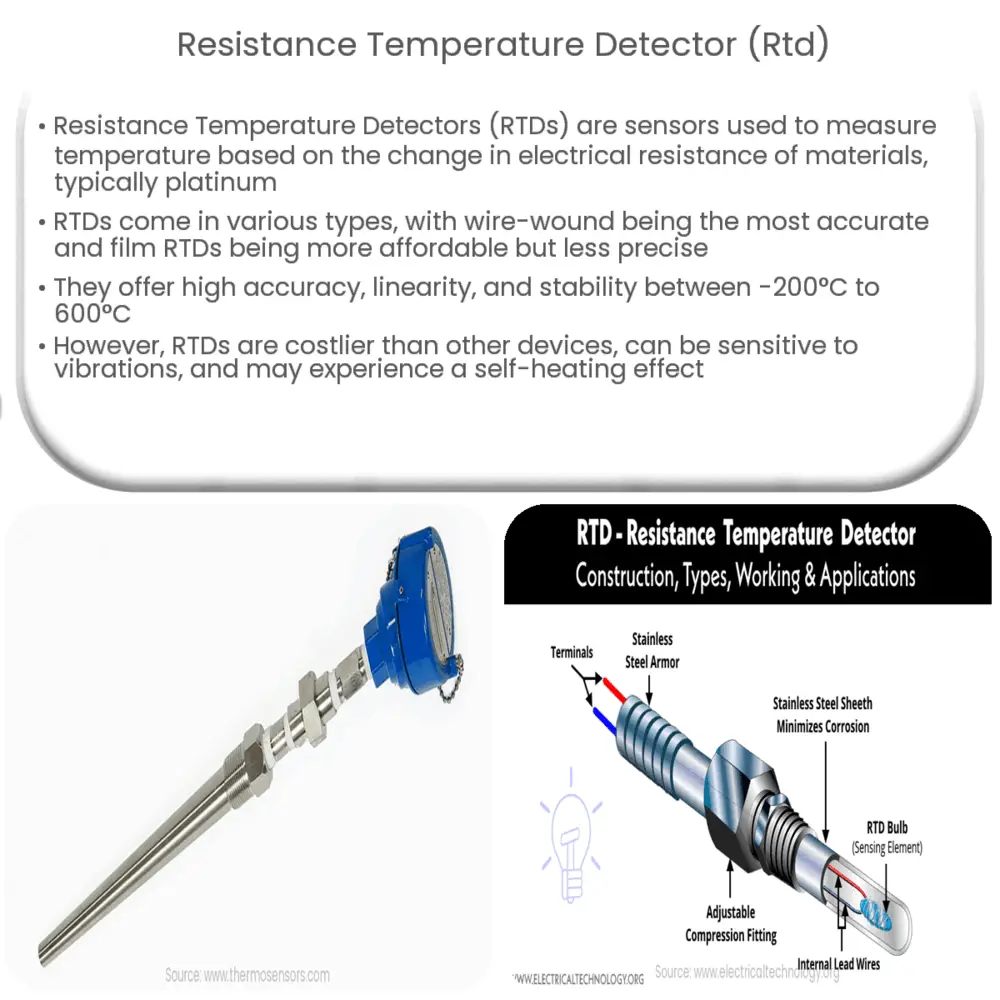

Explore the world of Resistance Temperature Detectors (RTDs), their working principle, types, applications, and limitations in our comprehensive guide.

Understanding Resistance Temperature Detectors (RTDs)

A Resistance Temperature Detector (RTD) is a type of sensor used in measuring temperature. Its functioning relies on the principle that electrical resistance of a material changes with temperature. Typically, these detectors are made from pure platinum due to its linear resistance-temperature relationship, stability and repeatability.

Working Principle of RTDs

The operation of an RTD is based on the principle of change in electrical resistance of a material with respect to its temperature. As the temperature changes, the resistance of the RTD element also changes. This change in resistance can then be measured and converted into a temperature reading.

Types of RTDs

- Wire-Wound RTDs: These are the most common and accurate type of RTDs. They consist of a wire wrapped around a ceramic or glass core.

- Film RTDs: In these, the platinum is deposited on a substrate. This type is less accurate than wire-wound RTDs but is cheaper and smaller in size.

Advantages of RTDs

- High accuracy: RTDs are known for their remarkable accuracy and stability, especially in the range of -200oC to 600oC.

- Linearity: The resistance-temperature relationship of RTDs is highly linear, which simplifies calibration and allows for easy temperature calculation.

- Long-term stability: Unlike other temperature sensors, RTDs maintain their accuracy and repeatability over a long period of time.

RTD Configurations

There are various configurations of RTDs that are designed to compensate for the effects of lead wire resistance. The most common of these are the 2-wire, 3-wire, and 4-wire configurations. Each of these configurations offers a different level of accuracy and complexity.

The 2-wire configuration is the simplest but least accurate due to the inability to compensate for lead wire resistance. The 3-wire configuration, on the other hand, provides a method of compensating for the lead wire resistance and is the most commonly used. Lastly, the 4-wire configuration offers the highest accuracy by completely eliminating the effect of lead wire resistance.

Applications of RTDs

RTDs find a wide variety of applications in different industries due to their high accuracy and stability. Here are a few of the significant applications:

- Process industry: RTDs are widely used in process industries such as chemical, petroleum, and food for precise temperature measurements.

- Electronics: In the electronics industry, RTDs help monitor and control temperatures in manufacturing processes.

- HVAC systems: RTDs are commonly used in Heating, Ventilation, and Air Conditioning (HVAC) systems for maintaining and controlling the temperature.

- Pharmaceutical industry: In pharmaceutical manufacturing, RTDs ensure the maintenance of the correct temperatures, critical to product quality.

Limitations of RTDs

Despite their many benefits, RTDs do come with a few limitations:

- Cost: RTDs are generally more expensive than other temperature measurement devices like thermocouples.

- Sensitivity to vibration and shock: Especially wire-wound RTDs can be sensitive to mechanical stress.

- Self-heating: When current passes through the RTD, it can heat up and cause minor errors in temperature reading. This is known as the self-heating effect.

Conclusion

In conclusion, Resistance Temperature Detectors (RTDs) are a reliable and highly accurate choice for temperature measurement. Their unique advantages, including linearity and long-term stability, make them a preferred choice in many industries. However, their use should be carefully considered depending on the specific requirements of the application, taking into account factors such as cost, sensitivity to mechanical stress, and self-heating. Nevertheless, with a proper understanding of their working, types, advantages, and limitations, RTDs can be effectively utilized for precise and reliable temperature measurement in various scenarios.