A pneumatic load cell is a force measurement device that uses air pressure to convert mechanical force into a pneumatic signal, suitable for hazardous environments.

Pneumatic Load Cell: An Introduction and Overview

Understanding Pneumatic Load Cells

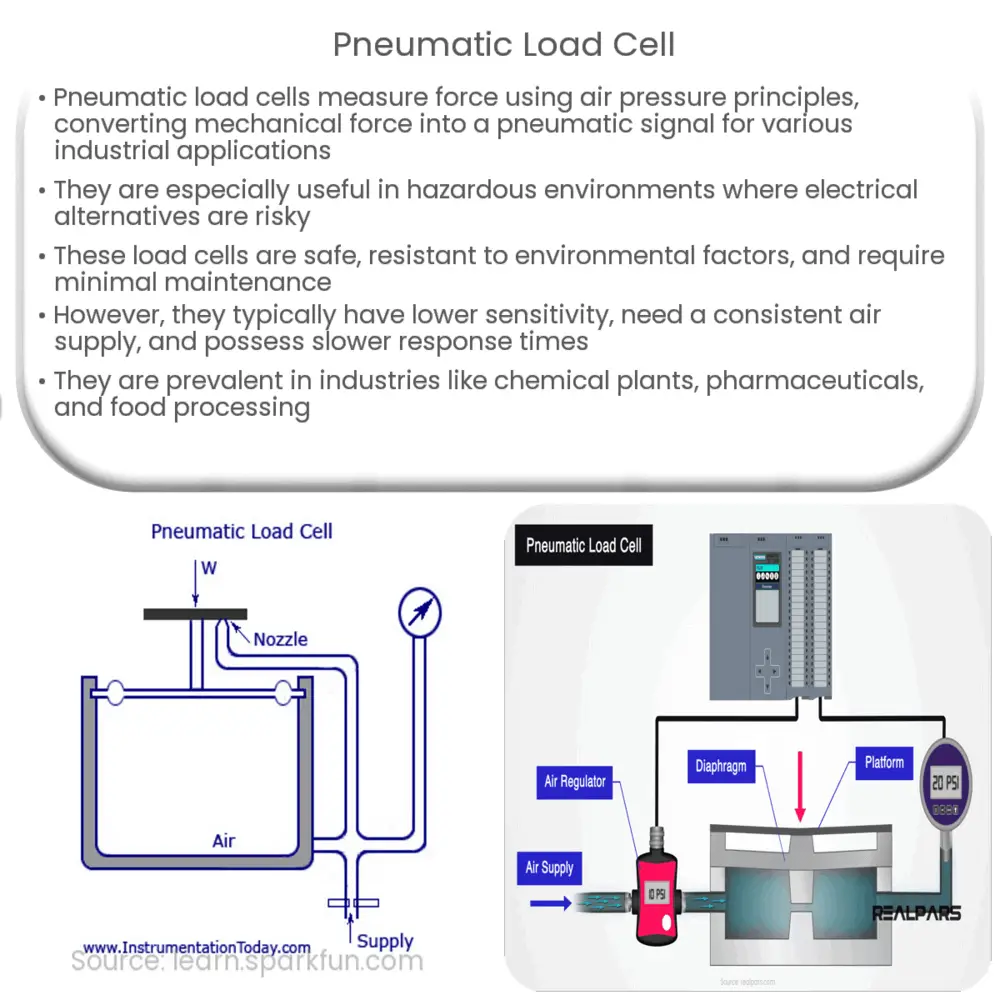

A pneumatic load cell is a type of force measurement device that operates using the principles of air pressure. It is designed to measure and convert mechanical force or weight into a pneumatic signal, which can be used to control and monitor processes in various industrial applications. Pneumatic load cells are particularly advantageous in situations where electrical load cells may pose a risk due to explosive or hazardous environments, as they are inherently safe and do not generate sparks.

Working Principle of Pneumatic Load Cells

The basic principle of a pneumatic load cell involves a diaphragm or a piston that is connected to the load being measured. As force is applied to the load cell, the diaphragm or piston compresses the air within the device, causing an increase in air pressure. This pressure change is proportional to the applied force and can be accurately measured using a pressure gauge or transducer.

There are two main types of pneumatic load cells: diaphragm-based and piston-based. In diaphragm-based load cells, the force applied on the load cell causes the diaphragm to deflect, which in turn changes the volume of the enclosed air chamber. This results in a change in air pressure that is proportional to the applied force. Piston-based load cells, on the other hand, consist of a piston that is directly linked to the load. As force is applied, the piston moves, compressing the air within the chamber and increasing the pressure proportionally to the load.

Advantages of Pneumatic Load Cells

Pneumatic load cells offer several key benefits over other types of load cells, such as strain gauge or hydraulic load cells. These advantages include:

- Inherently Safe: Pneumatic load cells do not produce sparks and are not affected by electrical disturbances. This makes them suitable for use in hazardous or explosive environments where electrical load cells may pose a risk.

- Resistance to Environmental Factors: Pneumatic load cells are less sensitive to temperature changes, moisture, and other environmental factors compared to electrical load cells. This results in more stable and accurate measurements in challenging conditions.

- Low Maintenance: Due to their simple design and minimal moving parts, pneumatic load cells typically require less maintenance than other types of load cells. This reduces downtime and increases the overall efficiency of the system.

- Overload Protection: Pneumatic load cells are inherently resistant to overloading, as the maximum pressure within the device is limited by the supply pressure. This prevents damage to the load cell and ensures reliable operation even in extreme situations.

Disadvantages of Pneumatic Load Cells

Despite their numerous advantages, pneumatic load cells also have some drawbacks that should be considered when selecting a load cell for a specific application:

- Lower Sensitivity and Resolution: Pneumatic load cells generally have lower sensitivity and resolution compared to strain gauge or capacitive load cells. This may make them unsuitable for applications requiring extremely precise measurements.

- Air Supply Requirements: Pneumatic load cells require a consistent and clean air supply to function properly, which can add complexity to the system and increase the overall cost of installation and operation.

- Slower Response Time: Due to the nature of air compression, pneumatic load cells typically have slower response times than their electrical counterparts. This may not be ideal for applications requiring rapid force measurements or real-time monitoring.

Applications of Pneumatic Load Cells

Pneumatic load cells are used across a wide range of industries and applications, including:

- Chemical and Petrochemical Plants: Pneumatic load cells are commonly used in chemical and petrochemical plants for measuring and controlling the weight of tanks, hoppers, and silos, where the presence of explosive or hazardous materials necessitates the use of intrinsically safe devices.

- Pharmaceutical Manufacturing: In pharmaceutical manufacturing processes, pneumatic load cells can be used to ensure accurate weighing and batching of ingredients, ensuring consistent product quality and adherence to regulatory standards.

- Food and Beverage Processing: Pneumatic load cells can be used in food and beverage processing facilities to monitor and control the weight of containers, mixers, and other equipment, helping to maintain consistent product quality and optimize production efficiency.

- Material Handling and Weighing Systems: Pneumatic load cells can be integrated into material handling and weighing systems, such as conveyor belts, to provide accurate weight measurements and control of bulk materials.

Conclusion

Pneumatic load cells offer a reliable and safe alternative to electrical load cells for force measurement in various industrial applications. While they may not be the best fit for all situations due to their lower sensitivity and resolution, pneumatic load cells provide an ideal solution for environments where electrical load cells could pose a risk. Their resistance to environmental factors and low maintenance requirements make them an attractive option for many industries, including chemical and petrochemical plants, pharmaceutical manufacturing, and food and beverage processing. Understanding the advantages, disadvantages, and potential applications of pneumatic load cells can help you determine if they are the right choice for your specific needs.