Explore the unique properties, manufacturing process, applications, and limitations of mu-metal, a nickel-iron alloy used for magnetic shielding.

Mu-Metal: An Overview

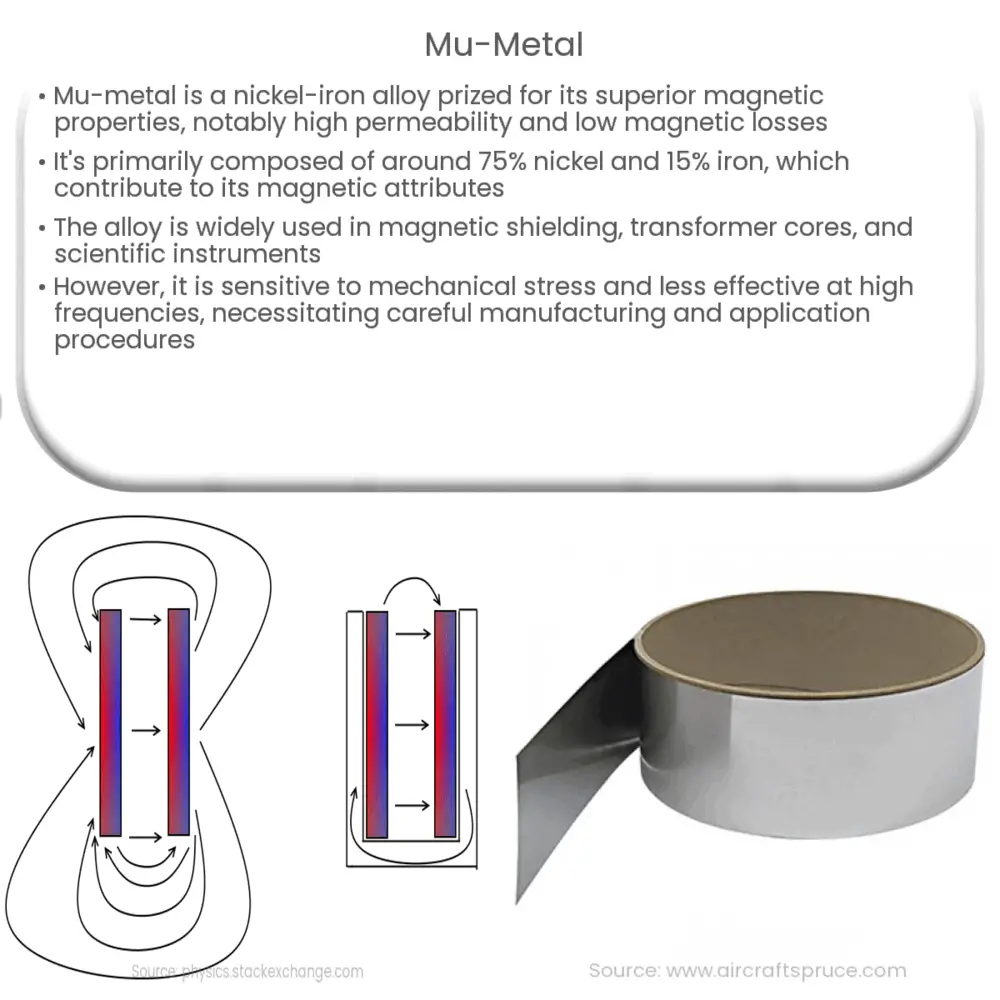

Mu-metal is a nickel-iron alloy that is well-known for its exceptional magnetic properties. It is often used in a wide variety of applications where high magnetic permeability and low magnetic losses are crucial. The term ‘mu’ in mu-metal originates from the Greek letter, typically used to signify magnetic permeability in physics.

Composition and Properties

The primary constituents of mu-metal are nickel and iron, typically consisting of approximately 75% nickel, 15% iron, plus copper and molybdenum. The high nickel content gives mu-metal its extraordinary magnetic properties, namely high permeability. This feature enables the material to attract and absorb a magnetic field, making it an excellent material for shielding sensitive electronic devices and equipment from magnetic fields.

- High Permeability: The most significant property of mu-metal is its high magnetic permeability, which allows it to absorb and dissipate magnetic energy effectively. This property makes mu-metal an ideal choice for use in shielding electronic devices.

- Low Magnetic Losses: The alloy’s unique composition also results in low hysteresis loss, referring to the energy loss in the form of heat due to magnetic field reversal. This feature is particularly useful in applications like transformer cores.

Manufacturing and Processing

Mu-metal requires careful handling and specialized processing to maintain its magnetic properties. The manufacturing process involves several steps, including initial forming, annealing, and final forming.

- Initial Forming: The first step in the manufacturing process involves shaping the mu-metal into its desired form. This could be in the shape of sheets, plates, or customized shapes based on the application.

- Annealing: After initial forming, the mu-metal undergoes an annealing process. This process involves heating the material in a controlled environment filled with a hydrogen atmosphere. The purpose of this step is to realign the grains of the alloy, thereby enhancing its magnetic properties.

- Final Forming: The final step involves shaping the annealed material into its final form. It’s critical to note that any subsequent mechanical stress or deformation can degrade the mu-metal’s magnetic properties, hence why this is the final step in the process.

Applications of Mu-Metal

Mu-metal’s unique magnetic properties make it highly useful in a wide range of applications, particularly those requiring magnetic shielding.

- Magnetic Shielding: The high permeability of mu-metal makes it an excellent material for magnetic shielding. It is widely used to shield sensitive electronic equipment from magnetic fields, reducing or eliminating unwanted interference.

- Transformers and Inductors: Due to its low hysteresis loss, mu-metal is a popular choice for the cores of electrical transformers and inductors. This property allows these devices to operate more efficiently and with less heat generation.

- Scientific Instruments: The alloy is also used in the construction of scientific instruments that require protection from magnetic fields. Examples include geophysics equipment, precision measurement devices, and magnetometers.

Limitations and Considerations

Despite its advantageous properties, there are some important considerations when working with mu-metal. As mentioned previously, the alloy is sensitive to mechanical stress, which can degrade its magnetic properties. Therefore, any final machining or forming must be done before the final annealing process. Additionally, while mu-metal is excellent at shielding static or low-frequency magnetic fields, it is less effective at high frequencies. This limitation is due to the alloy’s skin depth, which decreases as the frequency of the magnetic field increases.

Conclusion

In conclusion, mu-metal is a highly beneficial nickel-iron alloy known for its exceptional magnetic properties, primarily its high permeability and low magnetic losses. Its unique properties make it suitable for a wide array of applications, from magnetic shielding to the cores of transformers and inductors. However, due to its sensitivity to mechanical stress and limitations at high frequencies, care must be taken during manufacturing and application to maintain its magnetic properties. As technology continues to evolve and demand for effective magnetic shielding grows, mu-metal’s significance in various fields is likely to increase.