Explore the world of motor rewinding equipment, its importance, types, emerging trends, and factors to consider when choosing these tools.

Introduction to Motor Rewinding Equipment

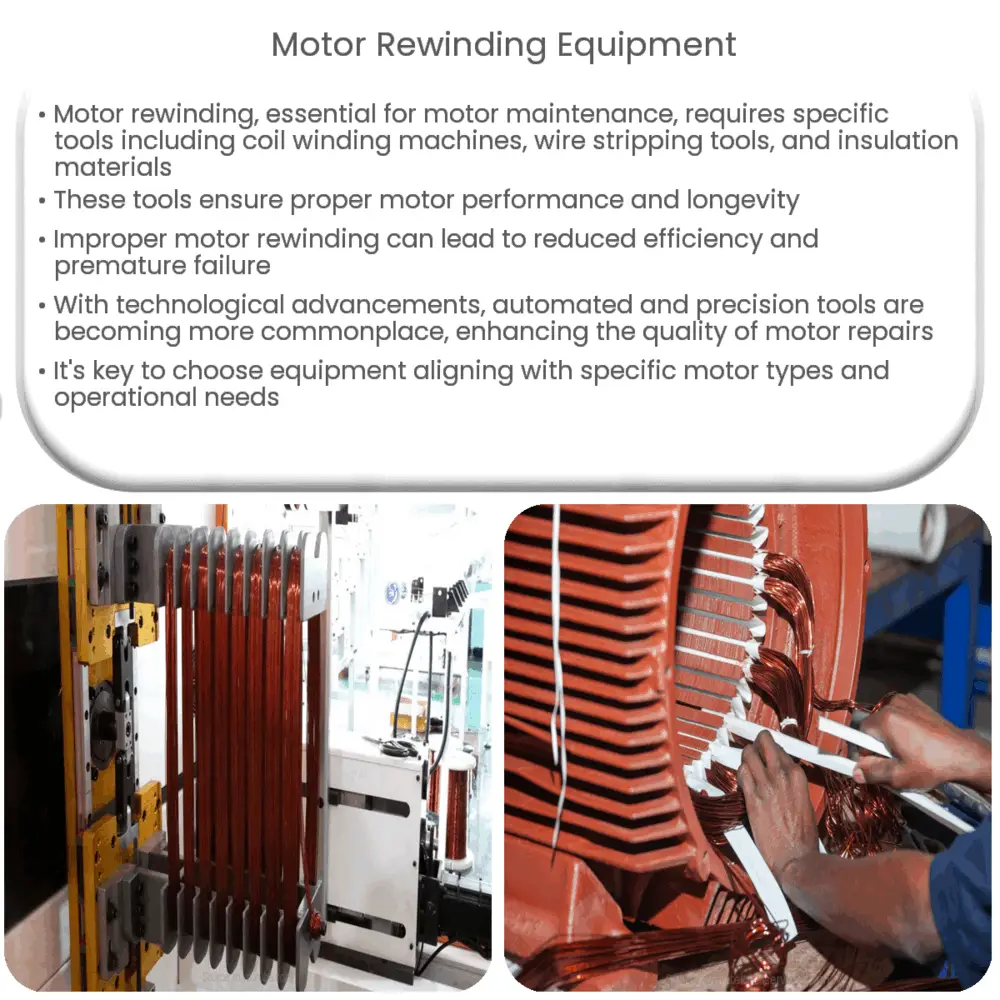

Motor rewinding is an essential process in the maintenance and repair of motors. It involves the replacement or repair of the motor windings, which are the copper wire coils that induce a magnetic field responsible for generating the rotational motion of the motor. To ensure efficiency and precision in this process, several types of motor rewinding equipment are employed.

Types of Motor Rewinding Equipment

Motor rewinding equipment varies depending on the type of motor and the scope of the work required. Here are some of the most commonly used tools and their roles in the rewinding process:

- Coil Winding Machine: This is a primary tool in the motor rewinding process. It helps in winding the wire coils onto the motor’s armature or stator. These machines can range from simple manual devices to more complex, programmable machines that can accommodate different motor sizes and winding patterns.

- Wire Stripping Tools: Wire stripping tools are used for removing insulation from the ends of the motor winding wires. This is important for ensuring proper electrical contact during connections.

- Insulation Materials and Tapes: Insulation materials prevent electrical shorts and protect the motor windings from heat and mechanical stress. Tapes, often made of materials like mica, polyester, or fiberglass, are used to secure and insulate the windings.

Importance of Proper Motor Rewinding Equipment

The choice of proper motor rewinding equipment is crucial for the performance and longevity of the motor. Improperly wound motors can lead to issues such as lower efficiency, higher operating temperatures, and a greater likelihood of premature failure. Therefore, investing in quality motor rewinding equipment and trained personnel can greatly improve motor performance and reliability, thereby reducing maintenance costs and downtime.

Emerging Trends in Motor Rewinding Equipment

As with many industrial sectors, motor rewinding is seeing advancements with the integration of digital technology. Automated coil winding machines, precision wire stripping tools, and advanced insulation materials are becoming more commonplace. Furthermore, software is being developed to optimize winding patterns and troubleshoot potential issues before they become significant problems. These advancements are streamlining the motor rewinding process, increasing efficiency and improving the overall quality of motor repairs.

In the next part, we will discuss some specific examples of high-quality motor rewinding equipment, their features, and benefits, as well as considerations to keep in mind when choosing equipment for your motor rewinding needs.

Detailed Overview of Motor Rewinding Equipment

Let’s delve deeper into some specific equipment used for motor rewinding:

- Automatic Coil Winding Machines: These machines are designed to wind a precise number of turns, resulting in coils with consistent tension. They can accommodate a variety of wire sizes and coil dimensions, ensuring versatility for different motor types.

- Thermal Wire Stripping Tools: As opposed to traditional mechanical strippers, thermal wire stripping tools use heat to remove insulation. This results in a cleaner strip with less risk of damaging the conductor, providing better electrical connections.

- High-Performance Insulation Materials: Modern insulation materials are designed to withstand high temperatures and harsh environments, contributing to longer motor lifespan. For instance, Nomex paper is often used due to its superior thermal, chemical, and mechanical stability.

Considerations when Choosing Motor Rewinding Equipment

When choosing motor rewinding equipment, consider factors such as the type of motors you will be working with, the volume of motors you need to rewind, and the expertise of your staff. Automated coil winding machines can provide greater consistency and efficiency, but they also require a higher initial investment and skilled personnel to operate. Similarly, high-performance insulation materials may not be necessary for all motors, so it’s crucial to match the equipment to your specific needs.

Conclusion

In conclusion, the motor rewinding process plays a crucial role in maintaining the operational efficiency and longevity of motors. The right equipment, from coil winding machines to wire stripping tools and insulation materials, is essential to achieve the best results. As technology continues to advance, we can expect further improvements in motor rewinding equipment, allowing for even greater precision and efficiency in motor repair. Therefore, staying informed about these trends and investing in the right equipment are key steps towards optimizing your motor rewinding operations.