Linear Induction Motors (LIMs) are electric motors generating linear motion via electromagnetic induction, offering high efficiency and low maintenance in various applications.

Linear Induction Motor (LIM): A Comprehensive Introduction

Part 1: Understanding the Linear Induction Motor

A Linear Induction Motor (LIM) is a unique type of electric motor that has the potential to revolutionize various industries due to its distinctive characteristics. This article will provide an in-depth understanding of LIMs, their working principle, applications, and advantages over traditional motors.

1. What is a Linear Induction Motor?

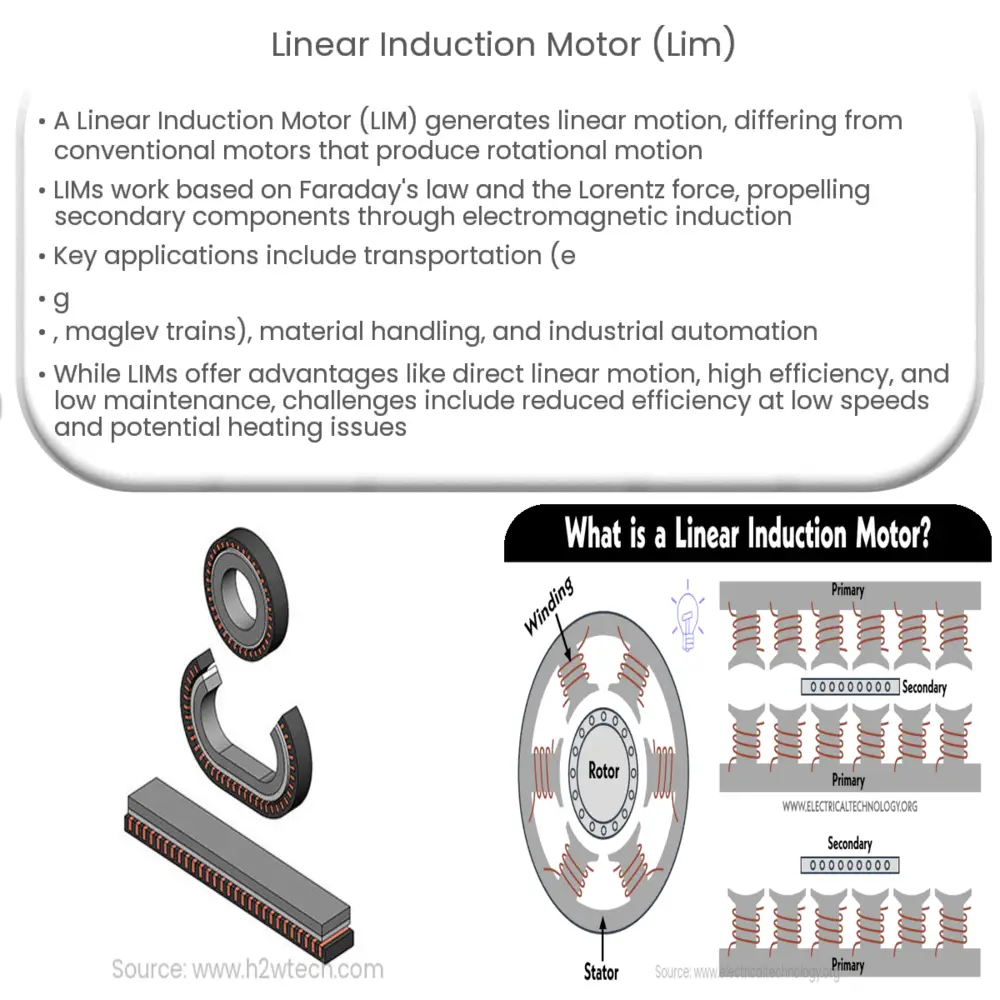

A Linear Induction Motor is a type of alternating current (AC) electric motor that generates linear motion instead of rotational motion, as seen in conventional motors. LIMs achieve this by replacing the traditional stator and rotor arrangement with a linear primary and secondary, respectively. The primary contains the electrical windings, while the secondary is usually a flat or slightly curved conductive plate.

2. Working Principle of a Linear Induction Motor

The working principle of a LIM is based on Faraday’s law of electromagnetic induction and the Lorentz force. When an alternating current flows through the primary windings, it creates a magnetic field that travels along the length of the motor. As this magnetic field intersects the conductive secondary, it induces an electric current in the secondary, known as the eddy current.

The interaction between the magnetic field generated by the primary and the induced eddy current in the secondary creates a force, known as the Lorentz force. This force propels the secondary in a linear direction, resulting in linear motion. The speed and direction of the secondary’s motion can be controlled by adjusting the frequency and phase of the AC current supplied to the primary windings.

3. Applications of Linear Induction Motors

Linear Induction Motors have found various applications across different industries due to their ability to produce linear motion directly, eliminating the need for mechanical transmission components such as gears and pulleys. Some of the prominent applications of LIMs include:

- Transportation: LIMs are used in magnetic levitation (maglev) trains, where they provide propulsion and levitation. Due to their high efficiency and low maintenance requirements, they have become the preferred choice for high-speed rail systems.

- Material Handling: LIMs are employed in conveyor systems, automated storage and retrieval systems, and other material handling applications, where they offer precise control, high speed, and low maintenance.

- Industrial Automation: The linear motion generated by LIMs is beneficial in various automation processes, including robotic arms, pick-and-place machines, and CNC machines.

4. Advantages of Linear Induction Motors

Linear Induction Motors offer several advantages over traditional motors, which make them suitable for various applications. Some of the key benefits include:

- Direct Linear Motion: LIMs provide direct linear motion without the need for mechanical transmission systems, reducing the complexity and maintenance requirements of the overall system.

- High Efficiency: LIMs are known for their high efficiency, as they eliminate energy losses associated with mechanical transmission components. This translates into energy savings and reduced operating costs.

- Low Maintenance: Due to the absence of mechanical components such as gears and pulleys, LIMs require less maintenance, making them ideal for applications where reliability and minimal downtime are crucial.

- Flexible Design: The design of LIMs can be easily customized to suit specific applications, allowing for greater flexibility and adaptability.

- Dynamic Control: The speed, direction, and position of the secondary can be accurately controlled by adjusting the electrical input, offering precise and dynamic control over the linear motion.

5. Challenges and Limitations of Linear Induction Motors

Despite their numerous advantages, Linear Induction Motors also come with certain challenges and limitations that need to be considered:

- Lower Efficiency at Low Speeds: At low speeds, LIMs tend to have lower efficiency compared to their rotary counterparts due to higher end effects and lower power factor.

- Heating Issues: The secondary of a LIM can experience heating due to eddy currents, which may necessitate the use of cooling systems in some applications.

- Higher Initial Cost: LIMs can have higher initial costs compared to traditional motors, primarily due to the need for specialized components and engineering expertise.

Part 2: Conclusion

In conclusion, Linear Induction Motors offer a unique and efficient solution for generating linear motion in various applications. Their numerous advantages, such as direct linear motion, high efficiency, low maintenance, and flexible design, make them an attractive choice for many industries. However, it is essential to consider the challenges and limitations of LIMs, such as lower efficiency at low speeds, heating issues, and higher initial costs, when selecting the appropriate motor for a specific application. With continued research and development, LIMs hold the promise of further improving their performance and expanding their range of applications in the future.