Explore the world of iron core inductors, their structure, working principle, benefits, and applications in our detailed guide.

Introduction to Iron Core Inductors

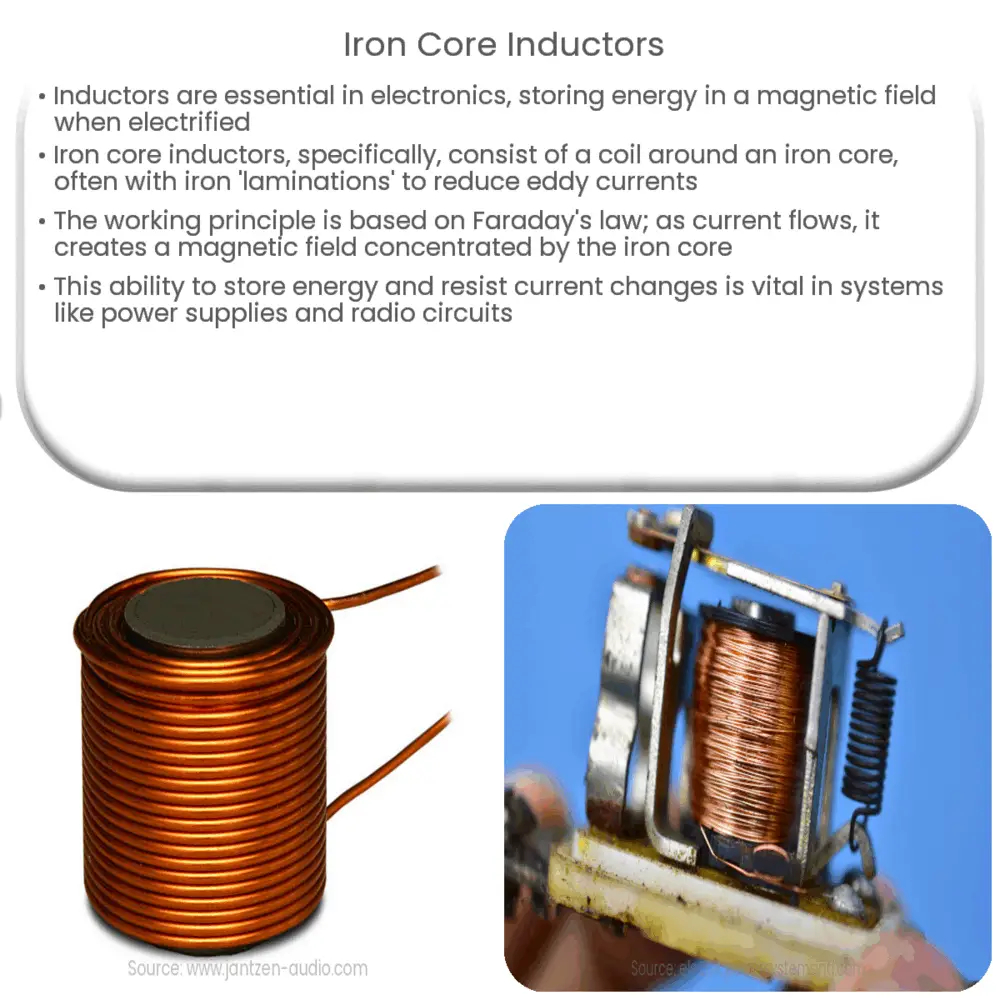

Inductors are fundamental components in the world of electronics, used in a wide range of applications from power supplies to radio transmitters. At their heart, inductors store energy in a magnetic field when an electrical current is passed through them. In this article, we will focus specifically on iron core inductors, their structure, how they work, and their benefits.

Structure of Iron Core Inductors

As the name suggests, an iron core inductor is made up of a coil of wire wrapped around an iron core. This core can be a solid piece of iron, but more commonly, it’s made up of small pieces of iron coated in an insulating material, known as ‘laminations’. These laminations help to reduce certain undesirable effects such as eddy currents.

- Coil: The coil in an iron core inductor is usually made of copper wire. This wire can be wound tightly or loosely, depending on the specific application and design requirements of the inductor.

- Core: The iron core provides a path for the magnetic field. Iron is chosen because of its strong magnetic properties. Its job is to concentrate the magnetic field created by the current flowing through the coil.

Working Principle

The basic principle behind the operation of an iron core inductor is Faraday’s law of electromagnetic induction. When an electric current is passed through the coil, it generates a magnetic field around the coil. This magnetic field is concentrated by the iron core, thereby increasing the inductance of the coil.

- When current is applied to the coil, it generates a magnetic field proportional to the current.

- This magnetic field induces a voltage in the coil. This is known as self-induction. The inductor resists changes in current due to this self-induced voltage.

- The iron core intensifies the magnetic field, increasing the amount of energy the inductor can store. The core also directs the magnetic field along its path, reducing loss and making the inductor more efficient.

The ability of the inductor to store energy and resist changes in current make it valuable in various electronic systems. For example, in power supplies, inductors are used to smooth out the output voltage. In radio-frequency circuits, they are crucial for tuning and impedance matching.

Benefits and Applications of Iron Core Inductors

Iron core inductors have several distinct advantages that make them desirable for use in electronic circuits. These benefits largely stem from the enhanced magnetic properties of the iron core.

- Increased Inductance: The iron core significantly increases the inductance per turn of the coil compared to an air-core inductor. This results in a higher ability to store energy.

- Compact Size: Due to the increased inductance, fewer turns of the coil are required for the same inductance. This makes the inductor more compact and lightweight.

- Eddy Current Reduction: The lamination of the iron core helps to reduce eddy currents, which can otherwise lead to power losses and heating.

These properties make iron core inductors widely applicable. They are used in power electronics, for instance in transformers and chokes for power supply units, where their energy storage capability and high inductance are crucial. In audio systems, they help in the filtering and equalization of signals. They are also used in various radio frequency applications, due to their tuning capabilities.

Limitations of Iron Core Inductors

Despite the numerous benefits, there are also some limitations associated with the use of iron core inductors. One main concern is the saturation of the core. When the magnetic field in the core reaches a certain limit (known as the saturation point), any further increase in current will not increase the magnetic field. This can distort signals and lead to inefficiencies.

Conclusion

In conclusion, iron core inductors are invaluable in many areas of electronics due to their high inductance, compact size, and energy storage capability. They are particularly advantageous in power supply and radio frequency applications. However, like any electronic component, they have limitations, and their use needs to be considered carefully in the context of the specific requirements of each application. As technology advances, we can look forward to improvements and more efficient utilization of these vital components in our electronic systems.