Explore the world of flow sensors: learn about their types, working principles, diverse applications, and latest advancements in this comprehensive guide.

Understanding Flow Sensors

A flow sensor is a critical piece of instrumentation, often used in various fields such as industry, science, and even in our homes. Understanding the functionality and applications of flow sensors can aid us in appreciating their pivotal role in our daily lives.

What is a Flow Sensor?

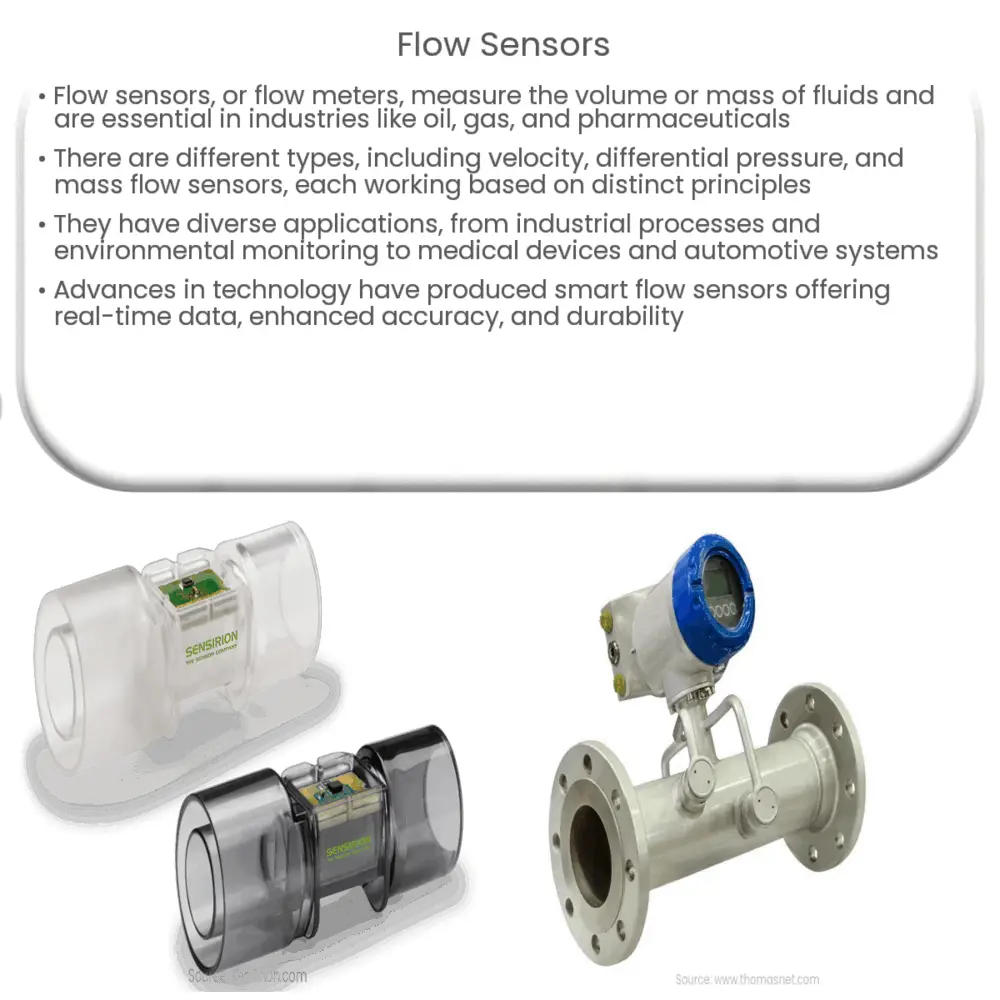

A flow sensor, also known as a flow meter, is a device designed to measure the volume or mass of a fluid – either liquid or gas – flowing through it. This device is crucial in numerous sectors, such as oil and gas, pharmaceutical, food and beverage, and water treatment industries, among others. The specific type of flow sensor utilized is typically determined by the nature of the fluid and the desired precision of the measurement.

Types of Flow Sensors

- Velocity Flow Sensors: These sensors measure the velocity of the fluid to determine the volume flow. Types of velocity flow sensors include turbine flow meters, vortex flow meters, and ultrasonic flow meters.

- Differential Pressure Flow Sensors: This type uses a constriction in the flow channel to create a pressure difference across two points. By knowing this difference and the properties of the fluid, one can calculate the flow rate. Examples of this type include orifice plates and Venturi tubes.

- Mass Flow Sensors: As the name suggests, these sensors measure the mass flow rate of a fluid, rather than the volumetric flow rate. A prime example of this type is a thermal mass flow sensor.

Working Principle of Flow Sensors

While there are numerous types of flow sensors, most operate on a similar basic principle. This involves sensing a change in some physical property of the fluid and translating this change into an output that can be measured. In velocity flow sensors, for example, the flow rate of the fluid is directly proportional to its velocity. Therefore, by measuring the velocity, the flow rate can be determined.

In the case of a differential pressure flow sensor, a constriction in the flow path (such as an orifice plate) causes a pressure drop. This drop in pressure is proportional to the square of the flow rate. By measuring this pressure difference, the flow rate can be calculated.

The concept of operation for a mass flow sensor, on the other hand, depends on the type of sensor used. In a thermal mass flow sensor, the heat carried away by the fluid is measured, which is directly proportional to the mass flow.

Each type of flow sensor has its own unique strengths and applications, making it possible to find the perfect sensor for virtually any need.

Applications of Flow Sensors

Given their diversity and adaptability, flow sensors find their utility in a variety of applications. Let’s look at some examples:

- Industrial Processes: Flow sensors are often used to monitor and control fluid flow in manufacturing or chemical processing plants. This ensures efficient and safe operation of the system.

- Environmental Monitoring: These devices are key in monitoring water and air quality, wastewater treatment processes, and even in climatology studies where precise measurements of fluid flows are required.

- Medical Applications: In the healthcare sector, flow sensors play a critical role in various medical devices such as ventilators, anesthesia machines, and dialysis devices.

- Automotive: In vehicles, flow sensors measure the flow of fuels, coolants, and air, thus enhancing fuel efficiency and performance.

Choosing the Right Flow Sensor

With numerous flow sensors available, choosing the right one can be a daunting task. However, understanding the nature of the fluid (viscosity, density, etc.), the required accuracy, and the specific application environment can guide the selection process. Furthermore, one must consider factors such as ease of installation, maintenance requirements, and cost.

Advancements in Flow Sensor Technology

Flow sensor technology is continually evolving. The push towards digitization has seen the development of smart flow sensors. These sensors, equipped with advanced communication capabilities, can provide real-time data, predictive maintenance alerts, and enhanced accuracy. Additionally, advancements in materials and sensor designs have led to more durable, reliable, and accurate flow sensors, able to withstand harsh environments and aggressive fluids.

Conclusion

In conclusion, flow sensors are indispensable tools in numerous fields, from industry to environmental monitoring to healthcare. Understanding the operation and applications of these devices allows us to better appreciate the technology that keeps our world running smoothly. As advancements in flow sensor technology continue, we can expect to see even more efficient and versatile applications that will further enhance our ability to monitor and control fluid flow in various scenarios.