Explore the signs of Electrostatic Discharge (ESD), its impact on electronics, and effective measures to control and prevent ESD damage.

Understanding Electrostatic Discharge (ESD)

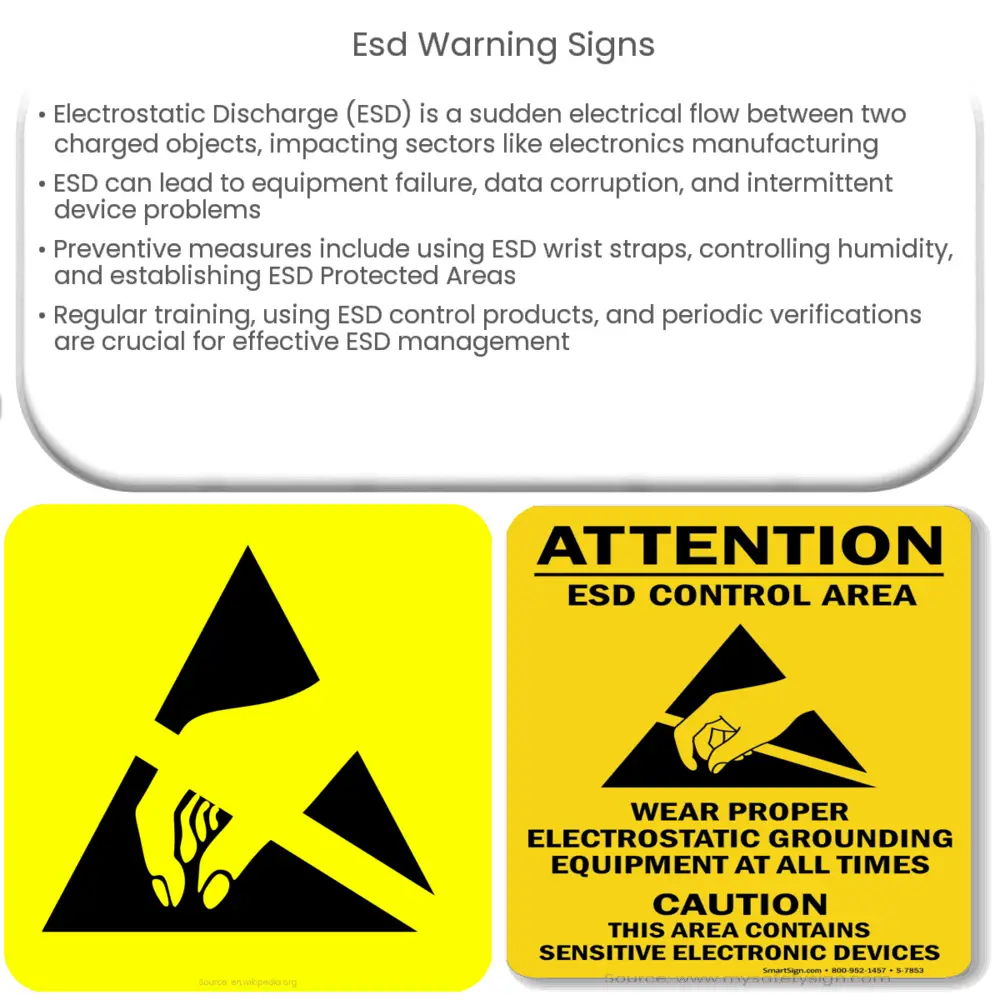

Electrostatic Discharge, commonly referred to as ESD, is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. ESD can be a serious issue in various fields such as electronics manufacturing, the semiconductor industry, and other high-technology sectors.

ESD Warning Signs

The initial indications of ESD are often subtle, but they can be catastrophic for electrical components and systems. Here are some of the warning signs that indicate potential ESD threats:

Measuring and Preventing ESD

While ESD damage can often be challenging to detect, various tools and techniques can help identify and prevent it. These include:

These steps can help mitigate ESD’s effects, but it is essential to remain vigilant, as the symptoms of ESD can often be non-obvious. Developing and adhering to a strict ESD control program is key to safeguarding sensitive electronic components and systems.

ESD Control Procedures

Having a robust ESD control procedure in place can significantly reduce the risk of ESD-related damage. Here are some elements that an effective ESD control procedure should include:

ESD and Quality Assurance

The effective control of ESD is also an essential part of quality assurance in many industries. The International Electrotechnical Commission (IEC) has established a standard known as IEC 61340-5-1. This standard outlines the basic requirements for the protection of electronic items from ESD damage and offers guidelines for an effective ESD control program. Implementing these standards can help organizations improve their quality assurance processes and reduce product failures related to ESD.

Conclusion

In conclusion, understanding and recognizing the signs of Electrostatic Discharge (ESD) is crucial in fields where electronic components and systems play a vital role. ESD can cause significant damage, resulting in equipment failure, data loss, and major disruptions in productivity. By implementing a robust ESD control program, including regular training, usage of ESD control products, and periodic verification, the risk of ESD can be significantly reduced. The adherence to internationally recognized standards like IEC 61340-5-1 can further enhance ESD control and contribute to improved quality assurance. It’s essential to be vigilant, proactive, and responsive to effectively prevent and manage ESD in sensitive electronic environments.