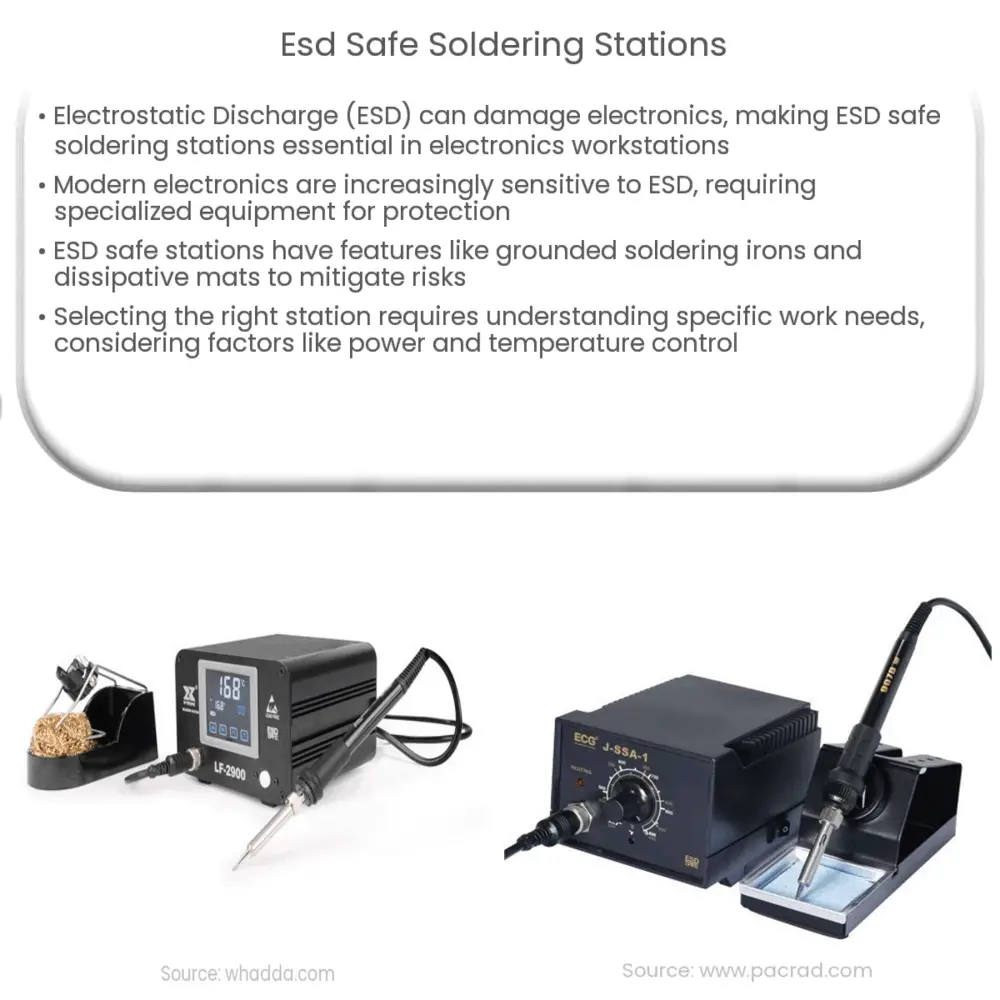

Explore the significance of ESD safe soldering stations in electronics, their key components, and factors to consider when choosing one.

Understanding ESD Safe Soldering Stations

Electrostatic Discharge, often abbreviated as ESD, is a rapid and unexpected flow of electricity that occurs when electrically charged objects come into contact or close proximity. In sensitive electronics manufacturing and repair, ESD can lead to substantial damage, resulting in significant losses. ESD safe soldering stations, thus, become an integral part of any electronics workstation.

The Importance of ESD Safety

Modern electronics are becoming increasingly miniaturized and complex. As a result, they are also becoming more sensitive to Electrostatic Discharge (ESD). A single ESD event can lead to device failure or cause latent damage that degrades performance over time. This sensitivity to ESD necessitates the use of ESD safe soldering stations.

What Constitutes an ESD Safe Soldering Station?

An ESD safe soldering station is designed to mitigate the risks associated with electrostatic discharge. This type of station is built with materials that are designed to disperse static charges, helping to prevent a buildup of static electricity that could lead to an ESD event. Moreover, the design and the features of the station itself aim to create an environment where static electricity is not easily generated.

Key Components of an ESD Safe Soldering Station

- Soldering Iron: The soldering iron in an ESD safe station typically has a grounded tip. This ensures any static charge that could potentially be transferred to the device being worked on is directed away, maintaining the integrity of the device.

- ESD Safe Mat: These mats are made of static dissipative materials and are typically connected to an earth ground. They provide a safe place to put the electronics being worked on.

- ESD Wrist Strap: An ESD wrist strap is worn by the operator. It’s designed to prevent a charge from building up on the person, which could be discharged to a device.

Choosing the right ESD safe soldering station requires a keen understanding of the requirements of your work. Therefore, it’s crucial to select a station that suits your specific needs. In the next part of this article, we will explore the factors to consider when choosing an ESD safe soldering station, and discuss the top ESD safe soldering stations available on the market.

Factors to Consider When Choosing an ESD Safe Soldering Station

Selecting the most suitable ESD safe soldering station involves several considerations. A good starting point is understanding your requirements and the nature of the devices you’ll be working on. Factors like the power requirement of the soldering iron, temperature control abilities, the quality of the tip, and the overall build of the station are all crucial.

- Power: Depending on the type of work, the power requirements of the soldering iron can vary. For delicate electronics work, a lower power rating might be more suitable. Conversely, for larger components, a higher power rating would be necessary.

- Temperature Control: A soldering iron with precise temperature control is crucial. It not only ensures efficient work but also prevents potential damage to sensitive components from excessive heat.

- Quality of Tip: The tip of the soldering iron comes into direct contact with the components. Therefore, it’s important that it’s made of high-quality material that is both durable and provides effective heat transfer.

- Build Quality: Finally, the overall build quality of the soldering station, including its ESD safety features, should be robust. This guarantees a long-lasting and safe working environment.

Conclusion

In conclusion, an ESD safe soldering station is a necessity in the realm of electronics. The delicate and intricate nature of modern electronic components renders them highly susceptible to damage from Electrostatic Discharge. To ensure the longevity and functionality of these devices, it is paramount to equip your workstation with an ESD safe soldering station. These stations, with their key components like a grounded soldering iron, ESD safe mats, and ESD wrist straps, form a protective shield against potential ESD events.

When choosing an ESD safe soldering station, it is important to consider the specific needs of your work. Factors such as the power requirements of the soldering iron, temperature control capabilities, quality of the tip, and the overall build quality of the station play significant roles in determining the right station for you. By carefully selecting an ESD safe soldering station, you can assure a safe, effective, and productive electronics workspace.