Discover the importance of ESD grounding points in protecting electronic components from electrostatic damage in our comprehensive guide.

Understanding the Importance of ESD Grounding Points

Static electricity is a common occurrence that most of us have experienced at some point. It can cause minor inconveniences like a shock from touching a doorknob, but in the realm of electronics, it can have much more severe consequences. In this scenario, electrostatic discharge (ESD) becomes a concern. ESD occurs when a sudden flow of electricity happens between two charged objects, often caused by contact, electrical shorting, or dielectric breakdown. This is where the critical concept of ESD Grounding Points comes into play.

What are ESD Grounding Points?

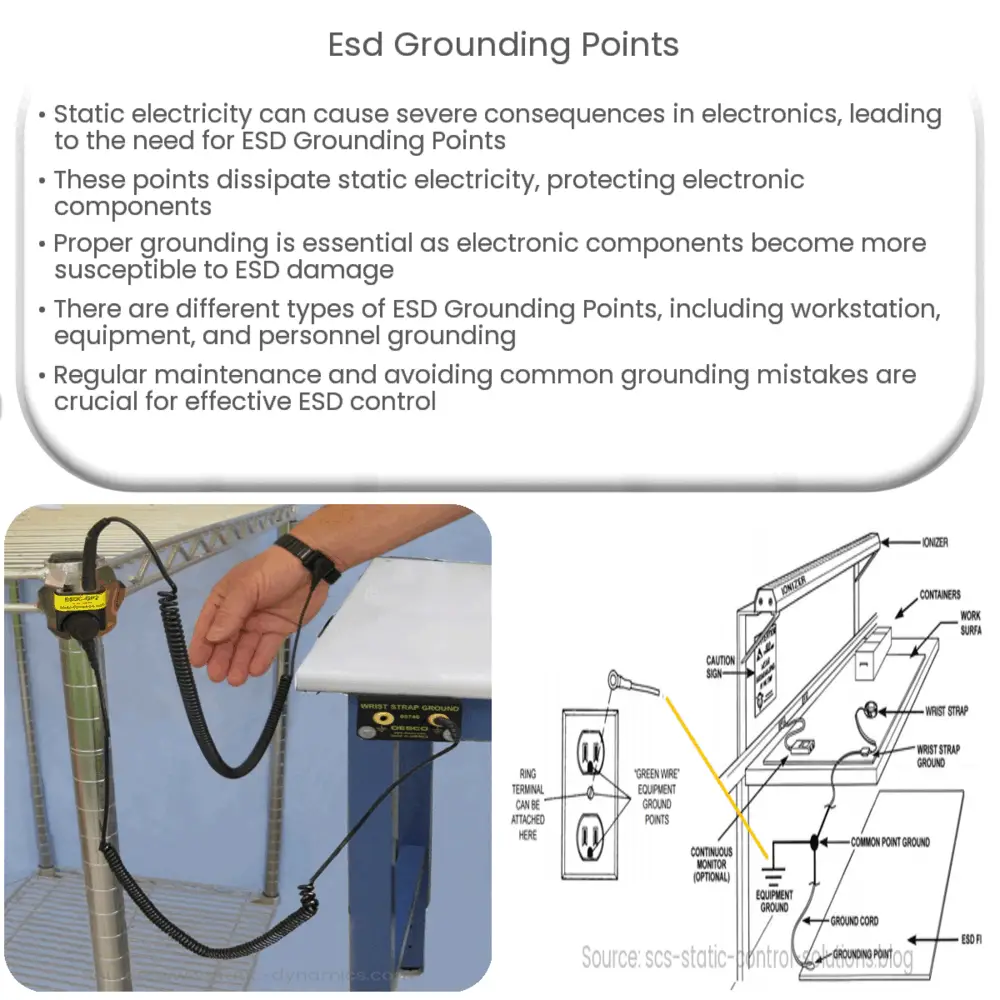

ESD grounding points are designed to provide a safe path for static electricity to dissipate to the ground, protecting sensitive electronic components from damage. Typically, these grounding points are part of an overall ESD protected area (EPA), which can include workstations, tools, and other materials used in handling electronics.

Importance of Proper Grounding

The significance of ESD grounding points cannot be overstated. As we deal with more advanced, miniaturized technology, electronic components have become more susceptible to ESD damage. Even a small ESD can cause latent or catastrophic damage to these components, potentially leading to significant financial losses due to equipment failure and downtime. The key to preventing this damage lies in the implementation of appropriate ESD control measures, with grounding being a fundamental component.

Types of ESD Grounding Points

- ESD Workstation Grounding: This is where ESD-sensitive work is performed. It involves grounding all components of the workstation, including the ESD mat, tools, and personnel. Grounding can be achieved using grounding wires and cords.

- Equipment Grounding: This involves grounding all electronic equipment used within the EPA. This can be done using three-wire AC power cords or separate grounding conductors.

- Personnel Grounding: This is achieved by grounding the personnel handling ESD-sensitive components. Grounding devices like ESD wrist straps and foot straps are typically used.

Regardless of the type, all grounding points need to be regularly checked for continuity and integrity. With appropriate grounding strategies in place, one can significantly reduce the risks associated with ESD and ensure the longevity and reliability of electronic components.

Implementing ESD Grounding Points

When setting up an EPA, creating an ESD grounding point should be a priority. It is a process that needs careful planning, as it involves not just the physical connection but also adherence to local and international ESD standards. To begin, identify all items that need grounding, then connect them to a common grounding point. This common point is then connected to the ground or the electrical earth. It is also crucial to maintain a resistance-to-ground reading of less than 1×109 ohms as per the ESD Association’s guidelines.

Maintaining ESD Grounding Points

Maintenance of ESD grounding points is a critical ongoing process. They should be tested regularly for their effectiveness and repaired or replaced as necessary. An effective ESD control program includes routine testing and record-keeping to ensure the maintenance of proper grounding.

Common Mistakes in Grounding

- Insufficient Grounding: A lack of sufficient grounding points can lead to an ineffective ESD control system. All ESD-sensitive components and personnel should be properly grounded.

- Ignoring Personnel Grounding: Human bodies can generate and hold a significant amount of static charge, hence the importance of personnel grounding. Ignoring this aspect can lead to major ESD-related damages.

- Grounding to a Non-Earth Ground: Grounding to a non-earth ground such as a water pipe can be ineffective, as it may not provide a low-resistance path to the earth.

Conclusion

In conclusion, ESD grounding points play a crucial role in protecting sensitive electronic components from potential ESD damage. By implementing a proper grounding system and avoiding common pitfalls, organizations can enhance the life and reliability of their electronic equipment, improving overall operational efficiency. However, simply installing ESD grounding points is not enough; they must be continuously tested and maintained to ensure they are functioning as intended. With a proper understanding and application of ESD grounding points, we can better safeguard our electronic infrastructure, making significant strides in electronic equipment reliability and sustainability.