Explore the principles, components, applications, and future prospects of Electrostatic Levitation Devices in this comprehensive article.

Understanding Electrostatic Levitation Devices

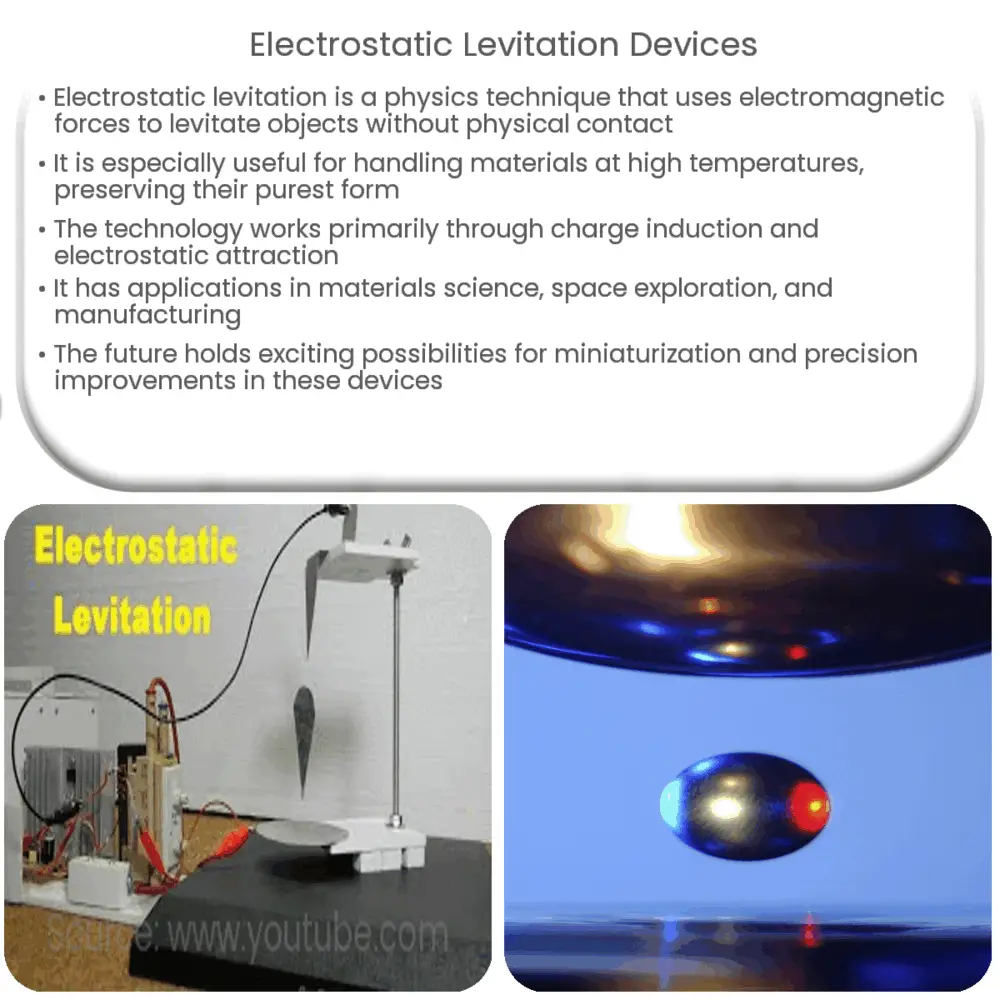

Electrostatic Levitation, a fascinating and relatively complex field of physics, has piqued scientific interest for many years. The fundamental idea behind electrostatic levitation is the use of electromagnetic forces to levitate or float objects in air, without the need for physical contact.

For a basic understanding, let’s define Electrostatic Levitation. It is a technique that uses electrostatic fields to provide a contact-free containment for handling materials. Typically, this method is used to manipulate materials at extremely high temperatures, where any physical contact would alter their properties or cause damage. In essence, it allows materials to be studied in their purest form.

Working Principle of Electrostatic Levitation Devices

The fundamental mechanism behind electrostatic levitation devices involves two primary elements: charge induction and electrostatic attraction.

- Charge Induction: This is the process where an object becomes electrically charged due to the influence of a nearby charged object without any physical contact. In the context of electrostatic levitation, the object that is to be levitated is induced with a charge.

- Electrostatic Attraction: Once the object has been charged, the electrostatic levitation device, which also carries an electric charge, creates an attractive force. This force counteracts gravity, thus enabling the object to float or levitate.

Key Components of Electrostatic Levitation Devices

- The Charging Electrode: This component is responsible for inducing the object with an electric charge. The degree of charge can be controlled to manipulate the levitation height.

- The Levitation Electrode: These are typically found beneath the object to be levitated. These electrodes create an upward force against gravity when they are charged, enabling levitation.

- The Feedback Control System: This is an essential component that stabilizes the levitated object. It adjusts the electrical charges in real-time to maintain the position of the levitated object, ensuring it doesn’t drift off course.

As we delve further into the potential applications and advances in electrostatic levitation, we open the door to innovative solutions across diverse industries. Whether it’s developing new materials or enhancing scientific experimentation, electrostatic levitation technology is revolutionizing our understanding of the world.

Applications of Electrostatic Levitation Devices

Electrostatic levitation technology has found applications in various sectors, fundamentally transforming the way processes are carried out.

- Materials Science: As it allows for contact-free handling of materials, electrostatic levitation is especially valuable in the field of materials science. Scientists can examine the properties of a sample at extremely high temperatures without worrying about contamination from a container.

- Space Exploration: The conditions in electrostatic levitation mirror those of zero gravity, making it an excellent tool for simulating and studying space conditions. NASA, for instance, uses this technology for various research purposes.

- Manufacturing Processes: Electrostatic levitation also benefits manufacturing, particularly in processes that require the manipulation of molten materials. The ability to handle these materials without physical contact reduces contamination risk and enhances process safety.

Future Prospects

As we stand on the cusp of a new era of technological advances, the future prospects for electrostatic levitation devices are exciting. One potential direction is the miniaturization of these devices, which could open up a whole new range of applications, such as the manipulation of micro or nano-scale objects in scientific and industrial settings.

Furthermore, advances in automation and control systems could lead to more precise and stable electrostatic levitation systems. These improvements could make these devices more user-friendly and accessible for a wider range of applications.

Conclusion

In conclusion, electrostatic levitation devices represent a potent tool in a variety of scientific and industrial domains. Their ability to allow contact-free handling of materials provides unique opportunities, from exploring the properties of new materials to enabling safe and contamination-free manufacturing processes. As technology continues to progress, we can expect to see even more innovative applications and improvements in the design and capabilities of electrostatic levitation systems. They truly exemplify the marvel of human ingenuity and our continuous pursuit of knowledge and discovery.