Explore the functionality, benefits, types, and applications of electromagnetic flow meters in various industries.

Introduction to Electromagnetic Flow Meters

An electromagnetic flow meter, also known as a magmeter, is a critical instrument that finds extensive application in a wide variety of industrial operations. Their key function is to measure the flow rate of conductive liquids and slurries, which includes but is not limited to, wastewater, chemicals, and foodstuffs.

Working Principle of Electromagnetic Flow Meters

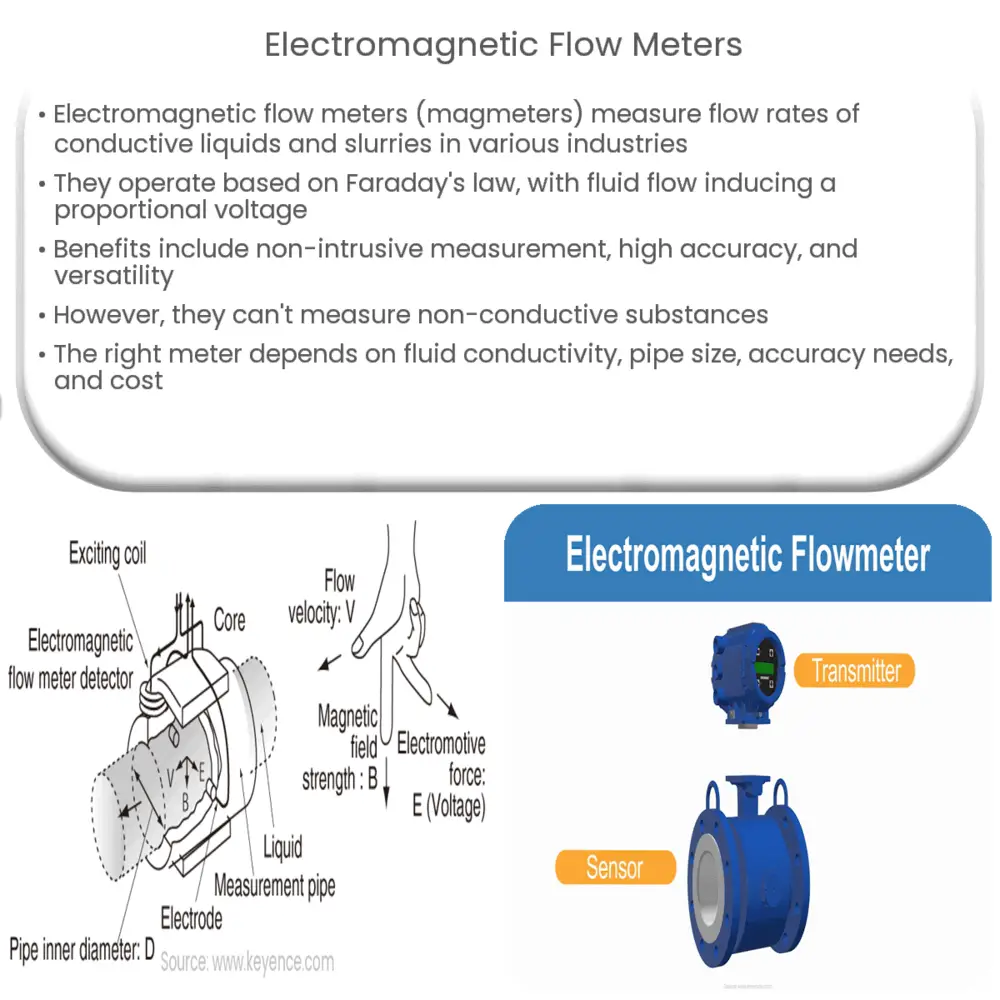

Electromagnetic flow meters function on Faraday’s law of electromagnetic induction, which posits that a voltage will be induced when a conductor moves through a magnetic field. In the case of a magmeter, the liquid or slurry to be measured is the conductor.

- The electromagnetic flow meter consists of a pair of electromagnetic coils positioned outside the flow tube. As the conductive fluid flows through the tube, it passes through the magnetic field created by these coils.

- The movement of the fluid generates a voltage proportional to its velocity, which is detected by electrodes embedded in the tube walls.

- This voltage is then converted into a flow rate, providing an accurate and reliable measurement.

Benefits of Electromagnetic Flow Meters

These innovative devices have a host of advantages that make them highly sought after for diverse applications. Here are some of the primary benefits:

- Non-intrusive Measurement: Electromagnetic flow meters do not have any moving parts. This allows for the measurement of flow without any physical obstruction, thereby eliminating potential pressure drops or blockages.

- High Accuracy: These flow meters are renowned for their accuracy. They can accurately measure the flow rate regardless of the physical properties of the fluid like temperature, pressure, or viscosity.

- Versatility: Their ability to measure a wide range of conductive liquids and slurries makes them versatile instruments suited to a plethora of industries.

Despite their advantages, one must be mindful of the fact that electromagnetic flow meters are limited to conductive fluids, and their application in measuring hydrocarbons or gases is ineffective due to these substances’ non-conductive nature.

Types of Electromagnetic Flow Meters

Based on their design and application, electromagnetic flow meters can be broadly classified into two types – insertion and full-bore.

- Insertion: These flow meters are installed within the pipe carrying the fluid. They are primarily used for large diameter pipes and open channels.

- Full-Bore: In these meters, the entire cross-section of the pipe is used for measurement, ensuring high accuracy and repeatability. They are widely used for a variety of industrial applications.

Choosing the Right Electromagnetic Flow Meter

When deciding on an electromagnetic flow meter, several factors should be taken into consideration:

- Fluid Characteristics: The fluid’s conductivity is paramount in this decision. The meter is less effective with low conductivity fluids.

- Pipe Size: The size of the pipe in which the flow meter is to be installed affects the choice between an insertion type and a full-bore type.

- Accuracy Requirements: While electromagnetic flow meters generally provide high accuracy, the exact needs should be considered. The accuracy may vary depending on the meter’s design and the application’s specific conditions.

- Cost: The purchase, installation, and maintenance costs should all be considered when making this decision.

Applications of Electromagnetic Flow Meters

Electromagnetic flow meters are used across a multitude of industries due to their reliability, accuracy, and versatility.

- Water and Wastewater Treatment: In these facilities, they measure and control the flow of various liquids.

- Chemical Industry: They measure the flow of aggressive and corrosive fluids, which could damage other types of flow meters.

- Food and Beverage: Electromagnetic flow meters, especially those with sanitary design, are used to measure the flow of food and beverage products, ensuring the quality and safety of these items.

- Mining: In the mining industry, they are used to measure the flow of abrasive slurries.

Conclusion

Electromagnetic flow meters are an invaluable tool in industries that work with conductive fluids. Their ability to provide accurate, non-intrusive measurements makes them a versatile and reliable choice for a multitude of applications. However, the selection of the right type of flow meter is crucial and should consider factors such as fluid conductivity, pipe size, accuracy requirements, and cost. Despite their limitations with non-conductive substances, the benefits they offer in handling a wide range of conductive fluids effectively make them an indispensable component in modern industrial processes.