A drop-out fuse is a safety device that interrupts excessive electrical currents in power distribution systems, protecting equipment from damage.

Understanding the Drop-out Fuse: An Essential Component for Electrical Safety

Introduction

Drop-out fuses, commonly known as expulsion fuses, are critical components used in electrical distribution systems to protect power lines, transformers, and other electrical equipment from damage due to overcurrent and short-circuit situations. These devices are designed to interrupt excessive electrical currents, preventing the risk of equipment failure, fires, and other hazards. In this article, we will discuss the principles behind the drop-out fuse, its construction, and applications in electrical systems.

Principles of Drop-out Fuses

A drop-out fuse functions by breaking an electrical circuit when the current flowing through it exceeds a predefined threshold. This threshold is determined by the fuse’s current rating, which is typically expressed in amperes. When an overcurrent or short-circuit situation occurs, the fuse element within the device melts, disconnecting the circuit and preventing further damage to the electrical system.

Drop-out fuses are designed to be sensitive to both overcurrent and temperature changes. In the event of a sustained overcurrent, the fuse element’s temperature will rise, causing it to melt and break the circuit. Additionally, these fuses are designed to respond to rapid temperature changes, such as those caused by a sudden short circuit, ensuring swift protection for the electrical system.

Construction of Drop-out Fuses

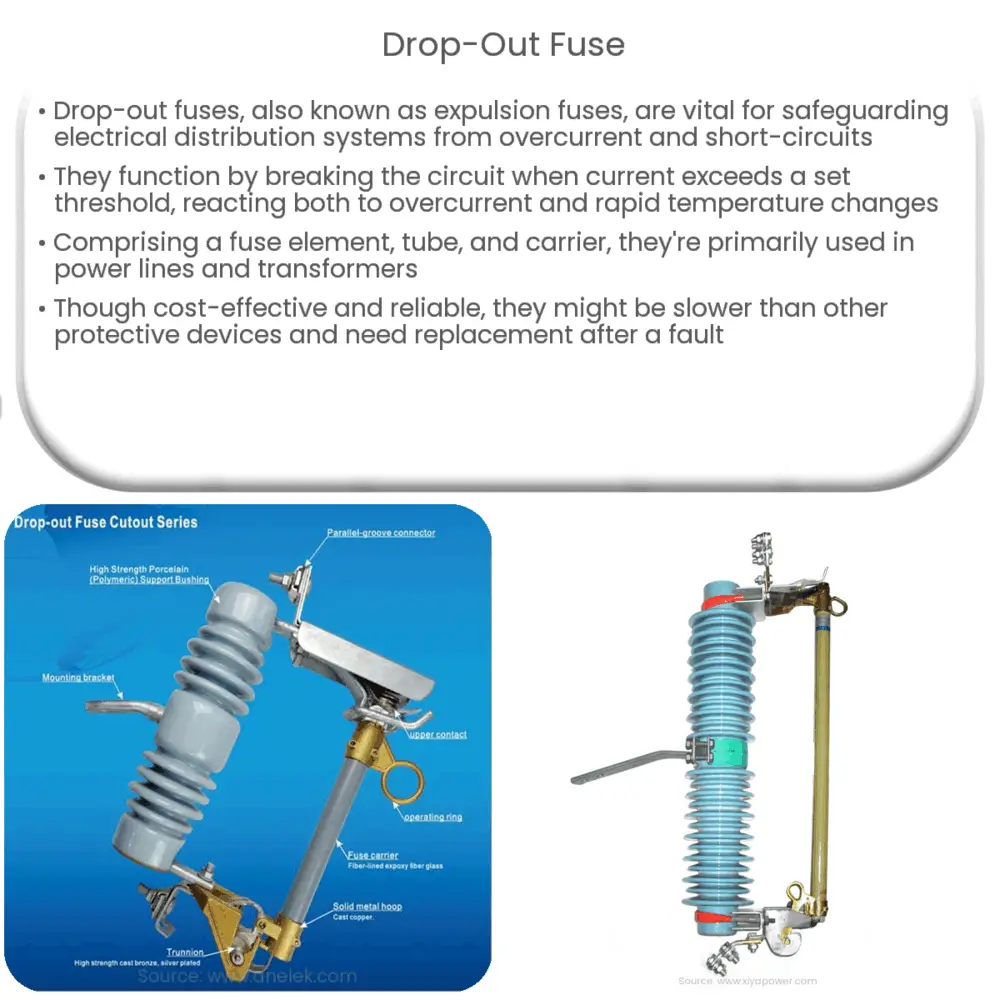

Drop-out fuses are typically composed of three main components: the fuse element, the fuse tube, and the fuse carrier. The fuse element is a thin strip of metal alloy, chosen for its specific melting characteristics at various current levels. It is enclosed within the fuse tube, which is often made of insulating materials like porcelain or glass fiber-reinforced plastic, to protect it from environmental factors and ensure proper insulation.

The fuse carrier is the external housing that holds the fuse tube in place, allowing for easy installation and removal. The carrier is often designed with a drop-out mechanism, which causes the fuse to automatically disengage from the circuit once the fuse element has melted. This drop-out feature is particularly useful in high-voltage applications, as it provides a visual indication of a blown fuse and allows for easy maintenance and replacement.

Applications of Drop-out Fuses

Drop-out fuses are commonly used in a variety of electrical distribution systems, particularly in overhead power lines and transformers. In these applications, they provide essential protection against overcurrents, short circuits, and other electrical faults that could lead to equipment damage or even fires. Additionally, drop-out fuses can be found in various industrial settings, such as manufacturing plants and mining operations, where electrical equipment protection is crucial.

In summary, drop-out fuses play a vital role in maintaining the safety and integrity of electrical distribution systems. By interrupting excessive currents and protecting valuable equipment from damage, these devices help to ensure the reliable and efficient operation of power networks around the world.

Maintenance and Replacement of Drop-out Fuses

Regular maintenance and inspection of drop-out fuses are essential to ensure their continued effectiveness in protecting electrical systems. Maintenance typically involves visual inspection for signs of wear, damage, or corrosion, as well as checking the fuse element’s integrity. If a fuse is found to be damaged or has reached the end of its service life, it must be replaced promptly to maintain system protection.

Replacing a drop-out fuse is a straightforward process, thanks to its user-friendly design. First, the power must be disconnected to ensure the safety of maintenance personnel. The fuse carrier can then be removed from its holder, allowing access to the fuse tube. The damaged fuse tube can be easily replaced with a new one, and the carrier reinstalled in its original position. Once the replacement is complete, the power can be reconnected, and the system returned to normal operation.

Selection and Sizing of Drop-out Fuses

Selecting the appropriate drop-out fuse for a given application is crucial to ensure adequate protection without causing nuisance tripping. Factors to consider when selecting a drop-out fuse include the current rating, voltage rating, and interrupting capacity. The current rating should be chosen based on the maximum continuous current the system is designed to handle, while the voltage rating must be suitable for the system’s operating voltage.

Furthermore, the interrupting capacity of the fuse should be sufficient to handle the maximum short-circuit current that could occur in the system. Inadequate interrupting capacity may result in the fuse failing to interrupt a short-circuit, potentially causing severe damage to equipment and posing a safety risk.

Advantages and Limitations of Drop-out Fuses

Drop-out fuses offer several advantages in electrical protection, including simplicity, cost-effectiveness, and reliable operation. Their simple design makes them easy to install and maintain, while their relatively low cost makes them an attractive option for budget-conscious applications. Furthermore, their reliable performance under various conditions ensures they provide consistent protection against overcurrents and short circuits.

However, drop-out fuses do have some limitations. They are generally slower to respond compared to other protection devices, such as circuit breakers, making them less suitable for applications requiring high-speed protection. Additionally, they provide only one-time protection, requiring replacement after a fault has occurred. This may be a disadvantage in situations where frequent fault clearing is necessary or where the cost of fuse replacements may become prohibitive.

Conclusion

In conclusion, drop-out fuses are essential components in electrical distribution systems, providing reliable protection against overcurrents and short circuits. Their simple design, cost-effectiveness, and ease of maintenance make them a popular choice for various applications. However, their limitations should be considered when selecting the appropriate protection device for a specific system. By understanding the principles, construction, and applications of drop-out fuses, professionals can make informed decisions to ensure the safety and integrity of their electrical networks.