Explore the workings, advantages, applications, and maintenance needs of Capacitor-Start Capacitor-Run Induction Motors in our in-depth guide.

Introduction to Capacitor-Start Capacitor-Run Induction Motors

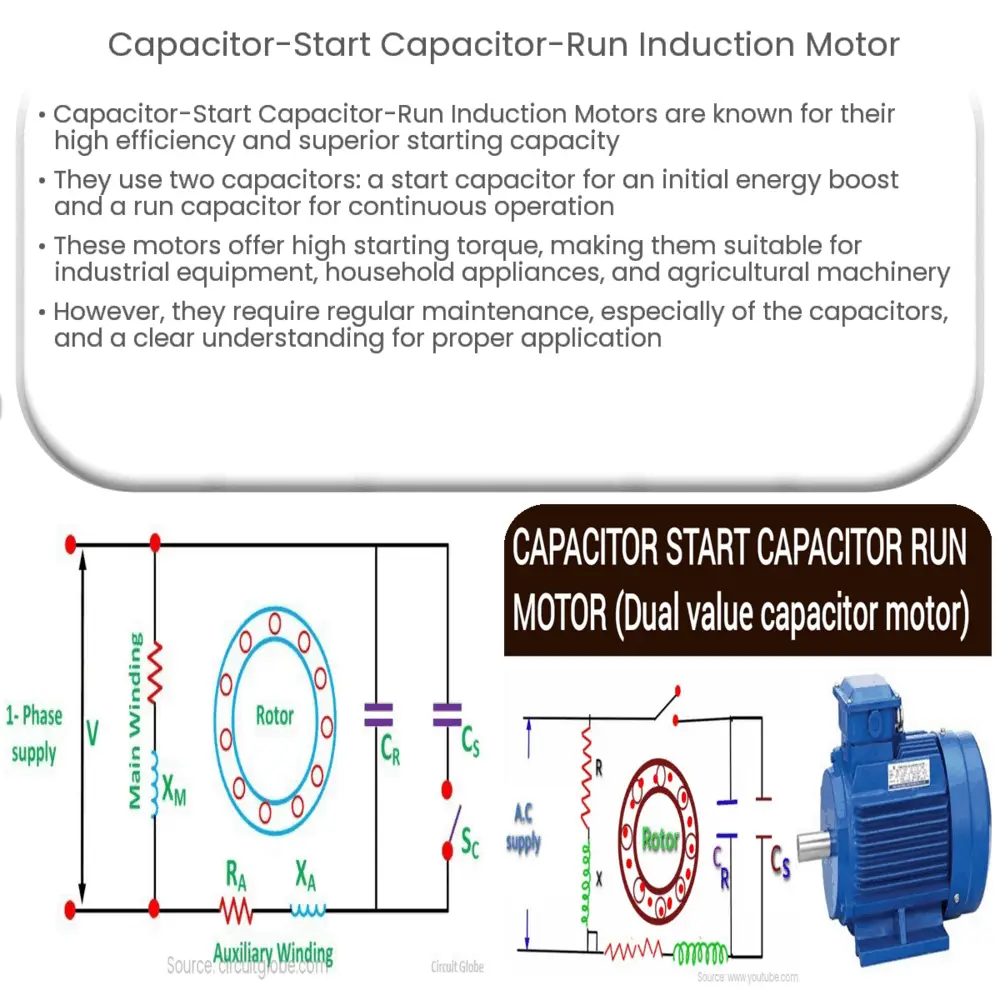

The world of electric motors presents a diverse array of designs, each with its unique advantages and specific applications. One such design that stands out due to its high efficiency and superior starting capacity is the Capacitor-Start Capacitor-Run Induction Motor.

This type of motor, as the name suggests, employs two capacitors in its design – a start capacitor and a run capacitor. The start capacitor provides an initial boost of energy at startup, while the run capacitor continues to provide energy throughout the motor’s operation.

How Capacitor-Start Capacitor-Run Motors Work

The main principle behind a Capacitor-Start Capacitor-Run Induction Motor involves creating a rotating magnetic field within the motor. This field is generated by the electrical current that passes through the motor’s main winding and the capacitor-driven auxiliary winding. The interaction between these two windings, and their respective magnetic fields, causes the motor to start and run.

At the onset, the start capacitor, connected in series with the auxiliary winding, provides a phase shift. This phase shift is critical for creating the initial rotating magnetic field necessary to start the motor. Once the motor reaches a specific speed, the start capacitor gets disconnected from the circuit by a switch. After this, the run capacitor, connected in parallel to the auxiliary winding, takes over. It provides the required phase shift for the motor to continue operation.

Key Advantages of Capacitor-Start Capacitor-Run Motors

-

High Starting Torque: This type of motor is known for its high starting torque, a characteristic that is highly beneficial for applications that require a strong initial force, such as pumps or compressors.

-

Improved Efficiency: The run capacitor improves the motor’s power factor, leading to more efficient operation and energy consumption.

-

Smooth Operation: With the run capacitor providing a continuous phase shift, these motors tend to operate more smoothly and quietly than other types of single-phase motors.

Despite these advantages, the design and operation of Capacitor-Start Capacitor-Run Induction Motors entail a level of complexity that should not be overlooked. An understanding of this complexity is crucial for their proper application and maintenance.

Applications of Capacitor-Start Capacitor-Run Induction Motors

The superior starting torque and energy efficiency of Capacitor-Start Capacitor-Run Induction Motors make them suitable for a wide range of applications. This includes, but is not limited to:

-

Industrial Equipment: These motors are extensively used in industrial machinery and equipment that require a high starting torque, such as pumps, compressors, and conveyors.

-

Household Appliances: Many household appliances, such as air conditioners, washing machines, and refrigerators, employ these motors due to their efficient and smooth operation.

-

Agricultural Machinery: In the agricultural sector, these motors are used in equipment like irrigation pumps, owing to their high starting torque.

Challenges and Maintenance

Although Capacitor-Start Capacitor-Run Induction Motors provide numerous benefits, they are not devoid of challenges. The use of capacitors introduces the risk of capacitor failure, which can result in reduced performance or complete motor failure. Therefore, regular inspection and maintenance of the capacitors is essential for ensuring the longevity and optimal performance of these motors.

It is also important to note that these motors require a certain level of expertise for their installation and maintenance. Incorrect capacitor values or faulty connections can lead to inefficient operation or even damage to the motor.

Conclusion

In conclusion, Capacitor-Start Capacitor-Run Induction Motors offer a unique combination of high starting torque and improved energy efficiency, making them an ideal choice for numerous applications across various industries. Their smooth and quiet operation further enhances their appeal. However, their complexity necessitates a clear understanding of their working principle and maintenance requirements. With proper installation and regular maintenance, these motors can provide reliable and efficient service for a long period of time.