Capacitive level sensors accurately measure liquid and solid levels in various industries, offering high accuracy, minimal maintenance, and versatility.

Understanding Capacitive Level Sensors: Principles, Applications, and Advantages

Introduction

Capacitive level sensors have emerged as a popular choice for measuring the levels of various liquids and solids in a wide range of industries. These sensors utilize the principles of capacitance to detect the presence or absence of a material in a container, providing accurate and reliable measurements. This article will explore the underlying principles, applications, and advantages of capacitive level sensors, offering valuable insights for industries considering this technology.

Principles of Capacitive Level Sensing

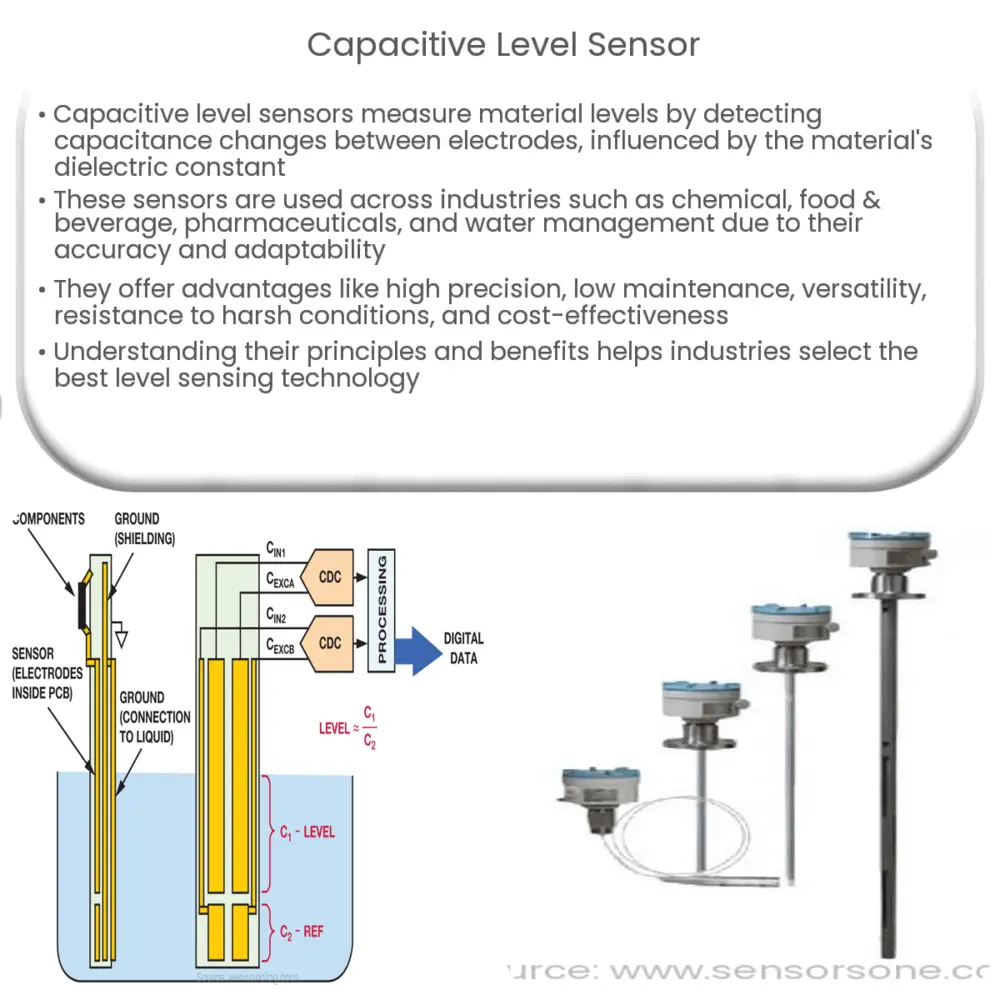

Capacitive level sensors work by measuring the change in capacitance between two conducting plates or electrodes. The capacitance between these plates is affected by the dielectric constant of the medium separating them. In a level sensing application, this medium consists of the material being measured (e.g., liquid or solid) and the air or empty space above it. As the level of the material changes, so does the dielectric constant of the medium, which in turn alters the capacitance. By detecting this change, the sensor can accurately determine the material’s level within the container.

Capacitive sensors can be designed as either contacting or non-contacting types, depending on the application requirements. Contacting capacitive sensors have electrodes that are in direct contact with the material, while non-contacting sensors have electrodes separated from the material by an insulating barrier, such as a plastic or glass window. Both types can provide accurate level measurements, but the choice depends on factors such as the material’s properties, the container’s design, and the environmental conditions.

Applications of Capacitive Level Sensors

Capacitive level sensors have found widespread use in numerous industries, including:

- Chemical and petrochemical industries: These sensors are suitable for monitoring the levels of various chemicals, including corrosive and toxic substances, due to their ability to withstand harsh environments and resist corrosion.

- Food and beverage: Capacitive level sensors can help ensure hygienic conditions by offering non-contact sensing options, making them ideal for measuring levels of liquids such as milk, juice, and beer.

- Pharmaceuticals: The accuracy and reliability of capacitive sensors make them a top choice for monitoring critical fluid levels in drug manufacturing and storage.

- Water and wastewater management: These sensors can be used to monitor water levels in storage tanks, reservoirs, and treatment plants, helping to optimize water distribution and prevent overflows or shortages.

- Bulk material handling: Capacitive sensors are capable of measuring the levels of various solid materials, such as grains, powders, and pellets, in silos, hoppers, and other storage systems.

Advantages of Capacitive Level Sensors

Capacitive level sensors offer numerous advantages over other sensing technologies, making them an attractive option for many applications:

- High accuracy: These sensors provide precise and reliable level measurements, ensuring optimal process control and inventory management.

- Minimal maintenance: Due to their non-mechanical nature and resistance to wear, capacitive sensors typically require little to no maintenance, reducing operational costs and downtime.

- Versatility: Capacitive level sensors can handle a wide range of materials, from liquids to solids, and can be configured for contacting or non-contact

ing applications, making them suitable for various industries and requirements. - Resistance to harsh environments: These sensors can withstand exposure to high temperatures, corrosive substances, and aggressive cleaning agents, ensuring reliable performance in demanding conditions.

- Cost-effectiveness: Capacitive level sensors offer a cost-effective solution for level measurement, as they typically have a lower initial investment and lower maintenance costs compared to other technologies.

Conclusion

Capacitive level sensors have established themselves as a reliable and versatile solution for measuring the levels of liquids and solids in a variety of applications. Their ability to provide accurate measurements with minimal maintenance requirements, combined with their resistance to harsh environments, make them an attractive choice for many industries. By understanding the principles, applications, and advantages of capacitive level sensing, companies can make informed decisions about the best technology to meet their specific needs.

References

- Fraden, J. (2016). Handbook of Modern Sensors: Physics, Designs, and Applications. Springer International Publishing.

- Gardner, J. W., & Varadan, V. K. (Eds.). (2001). Microsensors, MEMS, and Smart Devices. John Wiley & Sons.

- Ogata, K. (2009). System Dynamics. Prentice Hall.