Capacitive humidity sensors provide accurate, stable, and sensitive humidity measurements for various applications, including industrial, agricultural, and meteorological sectors.

Capacitive Humidity Sensors: An Overview

Introduction

Humidity plays a vital role in various applications, including industrial processes, agriculture, meteorology, and indoor climate control. As such, accurate measurement of humidity is essential for maintaining optimal conditions in these sectors. Capacitive humidity sensors are one of the most common and reliable devices for measuring humidity, due to their excellent performance, stability, and sensitivity. This article provides an in-depth overview of capacitive humidity sensors, covering their working principle, advantages, and common applications.

Working Principle of Capacitive Humidity Sensors

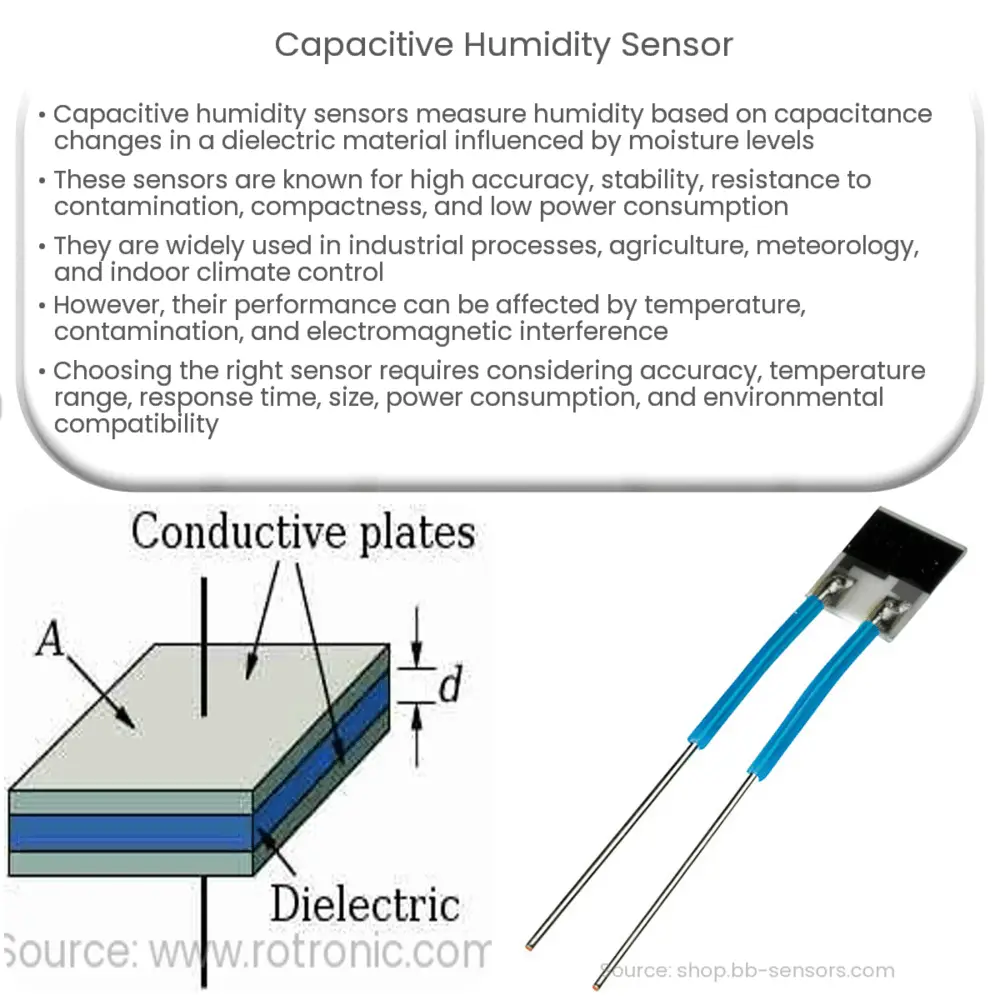

Capacitive humidity sensors operate on the principle of capacitance, which is the ability of a system to store an electrical charge. The sensor consists of two conductive plates, separated by a hygroscopic dielectric material. The dielectric material, typically a polymer or ceramic, exhibits a property known as relative permittivity (or dielectric constant), which varies with humidity levels. When the humidity increases, the water molecules are absorbed by the dielectric material, leading to an increase in its permittivity. This, in turn, results in a change in the capacitance between the plates, which can be measured and converted into a humidity reading.

Advantages of Capacitive Humidity Sensors

Capacitive humidity sensors offer several advantages over other types of humidity sensors, including:

- High accuracy and sensitivity: Capacitive sensors are known for their high accuracy, typically within ±2% relative humidity (RH) and fast response times, making them suitable for a wide range of applications.

- Stability: These sensors exhibit excellent long-term stability and minimal drift, which ensures consistent performance over time.

- Resistance to contamination: The use of robust dielectric materials in capacitive sensors minimizes the impact of contaminants, such as dust and dirt, on their performance.

- Compact size and low power consumption: Capacitive humidity sensors can be designed in small form factors and consume minimal power, making them ideal for use in portable devices and battery-powered applications.

Common Applications of Capacitive Humidity Sensors

Due to their high accuracy, stability, and versatility, capacitive humidity sensors are used in a wide range of applications, such as:

- Industrial processes: In industries like pharmaceuticals, food and beverage, and electronics manufacturing, maintaining precise humidity levels is critical for product quality and safety.

- Agriculture: Accurate measurement of humidity is essential for monitoring soil moisture, greenhouse conditions, and livestock environments to ensure optimal growth and health.

- Meteorology: Humidity sensors play a significant role in weather forecasting and climate research, providing valuable data for atmospheric studies and prediction models.

- Indoor climate control: These sensors are commonly used in HVAC systems to monitor and maintain comfortable humidity levels in residential, commercial, and industrial buildings.

Factors Affecting Capacitive Humidity Sensor Performance

While capacitive humidity sensors offer numerous advantages, certain factors can impact their performance and accuracy. Some of these factors include:

- Temperature: Temperature changes can cause variations in the capacitance of the sensor, leading to inaccurate humidity readings. To mitigate this, many capacitive humidity sensors incorporate temperature compensation mechanisms to ensure accurate measurements across a wide temperature range.

- Contamination: Although capacitive sensors are generally resistant to contamination, exposure to certain chemicals or aggressive environments may affect the dielectric material and alter the sensor’s performance. Regular maintenance and cleaning, as well as selecting appropriate materials for specific applications, can help prevent contamination-related issues.

- Electromagnetic interference (EMI): Capacitive sensors can be susceptible to EMI, which may cause inaccurate readings. Proper shielding and grounding techniques can help minimize the impact of EMI on sensor performance.

Selecting the Right Capacitive Humidity Sensor

When choosing a capacitive humidity sensor for your application, consider the following factors:

- Accuracy: Determine the required accuracy level for your application and choose a sensor that meets or exceeds this requirement.

- Operating temperature range: Ensure the sensor can operate within the temperature range specific to your application, and that it includes temperature compensation if necessary.

- Response time: Select a sensor with a response time that meets the needs of your application, considering factors such as the speed of environmental changes and the required measurement frequency.

- Size and power consumption: For portable or battery-powered applications, opt for sensors with small form factors and low power consumption.

- Environmental compatibility: Consider the sensor’s compatibility with the environment in which it will operate, taking into account factors such as exposure to chemicals, contaminants, and potential sources of EMI.

Conclusion

Capacitive humidity sensors are a popular choice for a wide range of applications due to their high accuracy, stability, and versatility. Understanding the working principle, advantages, and factors affecting their performance can help you make an informed decision when selecting the right sensor for your specific needs. By considering the key factors discussed in this article, you can ensure optimal performance and reliability from your capacitive humidity sensor.