The Buchholz relay is a protective device for oil-immersed transformers, detecting faults early to prevent damage and ensure power system reliability.

Buchholz Relay: A Comprehensive Overview

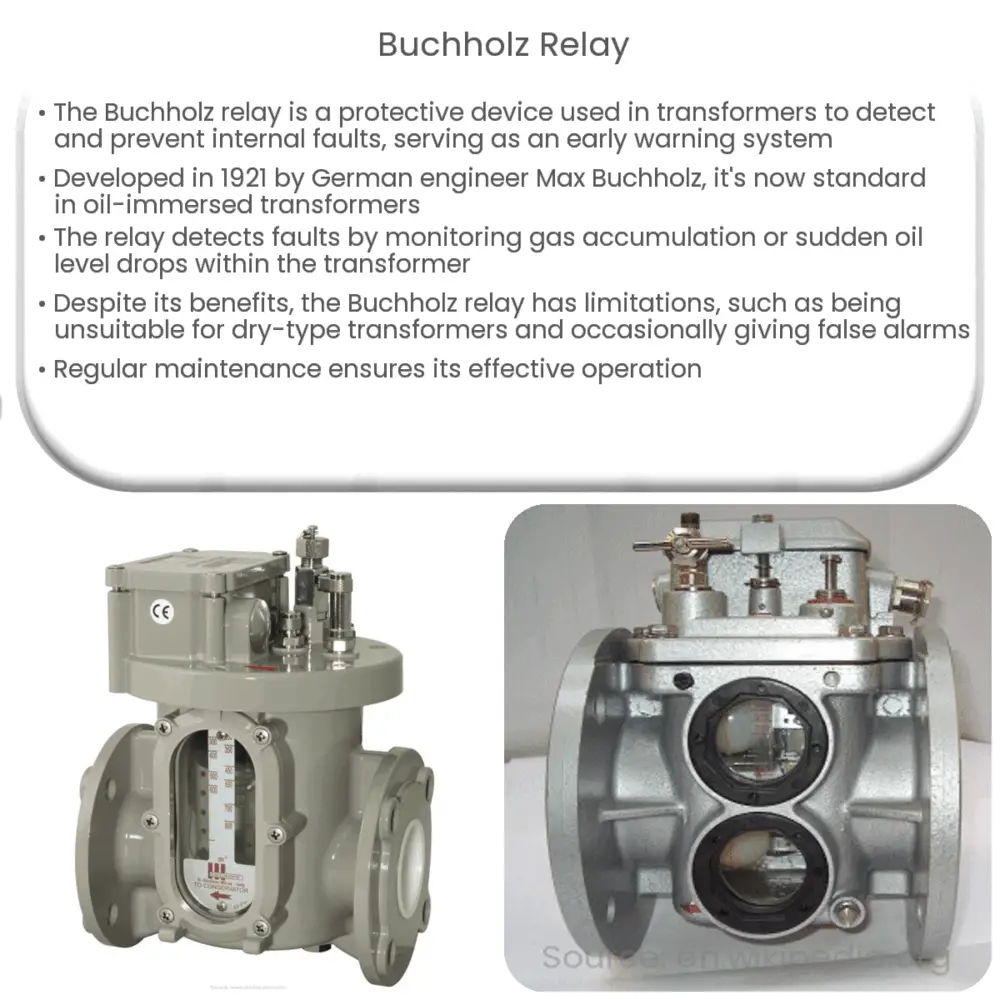

A Buchholz relay is a vital protective device used in transformers to detect and prevent faults. Transformers are essential components in power distribution systems, responsible for stepping up or stepping down voltage levels. However, they can develop internal faults, such as short circuits, insulation failure, or partial discharges. These faults can lead to excessive heating and gas formation within the transformer, which can damage the unit or cause it to fail altogether. The Buchholz relay serves as an early warning system to help prevent such incidents.

History and Development

The Buchholz relay, named after its inventor Max Buchholz, was first developed in 1921. Max Buchholz was a German engineer who sought to improve transformer safety by designing a device that could detect faults before they became severe. His invention has since been widely adopted and is now a standard component in oil-immersed transformers.

How a Buchholz Relay Works

A Buchholz relay is typically installed in the oil-filled pipe connecting the transformer tank to the conservator, a reservoir that holds the oil. The relay operates on the principle that gas is generated during a fault within the transformer. This gas accumulates in the relay chamber, causing a float to drop, which then activates a switch that sends a signal to a control panel or trips the circuit breaker. In some cases, the relay can also be triggered by a sudden drop in oil level due to a leak or rupture.

Types of Faults Detected

Buchholz relays can detect various types of faults within a transformer, including:

- Inter-turn short circuit: This fault occurs when the insulation between the transformer’s windings breaks down, causing a short circuit. The resulting current flow can generate excessive heat and gas.

- Core insulation failure: A fault in the insulation between the transformer’s core and windings can lead to a short circuit, generating heat and gas.

- Partial discharges: These occur when high voltage stresses cause electrical discharges in the oil, which can produce gas and lead to further insulation breakdown.

- Oil leakage or rupture: A sudden drop in oil level, due to a leak or rupture, can also trigger the Buchholz relay.

By detecting these faults early, the Buchholz relay helps prevent catastrophic failure and damage to the transformer, ensuring the reliability of the power distribution system.

Advantages of a Buchholz Relay

There are several advantages to using a Buchholz relay in oil-immersed transformers:

- Early fault detection: The relay’s ability to detect faults early can help prevent more severe damage, extending the life of the transformer and reducing maintenance costs.

- Simple and reliable operation: The Buchholz relay’s mechanical design is straightforward, with few moving parts, making it a reliable and low-maintenance device.

- Cost-effective: Installing a Buchholz relay is a relatively inexpensive way to improve the safety and reliability of a transformer.

Limitations of a Buchholz Relay

Despite its advantages, there are some limitations to using a Buchholz relay:

- Only for oil-immersed transformers: Buchholz relays are exclusively designed for oil-immersed transformers, and cannot be used with dry-type or air-cooled transformers.

- Not suitable for small transformers: Due to the size and design constraints, Buchholz relays are typically not used in smaller transformers, where alternative protection methods may be more suitable.

- False alarms: In some cases, the relay can be triggered by events not related to a fault, such as a sudden drop in oil temperature or the presence of air bubbles in the oil. These false alarms may lead to unnecessary shutdowns.

Preventative Measures and Maintenance

To ensure the proper functioning of a Buchholz relay, regular maintenance and inspections are necessary. Some of the key steps include:

- Periodic inspection: Regularly inspect the Buchholz relay for any signs of wear, corrosion, or damage. Check for any oil leaks around the relay or the connecting pipe.

- Oil analysis: Periodically test the transformer oil for dissolved gases, acidity, and moisture content. These factors can indicate the presence of faults or the need for oil replacement.

- Functional testing: Conduct routine tests to ensure the relay is functioning correctly. This includes simulating faults and verifying that the relay trips as intended.

- Training and awareness: Ensure that personnel responsible for transformer maintenance are familiar with the operation and maintenance of Buchholz relays.

Conclusion

The Buchholz relay is an essential protective device for oil-immersed transformers, providing early fault detection and helping to prevent catastrophic failures. By understanding the principles behind its operation, the types of faults it detects, and the necessary preventative measures, transformer operators can ensure the safety and reliability of their power distribution systems. Although it has some limitations, the Buchholz relay remains a cost-effective and reliable solution for protecting transformers and maintaining the stability of electrical grids.