Explore the workings, applications, pros, and cons of Series Wound DC Motors, with insights on their maintenance for optimal performance.

Introduction to Series Wound DC Motors

DC motors have a long-standing history of usage in many industries due to their simplicity, reliability, and efficiency. Among various types of DC motors, Series Wound DC motors are one of the most important and commonly used. Let’s dive into a detailed understanding of what Series Wound DC Motors are and how they function.

What is a Series Wound DC Motor?

In a Series Wound DC Motor, the armature and field windings are connected in series. This means the same current flows through the field winding and the armature. Because of this unique configuration, these motors exhibit distinct characteristics that make them suitable for specific applications.

Construction of Series Wound DC Motors

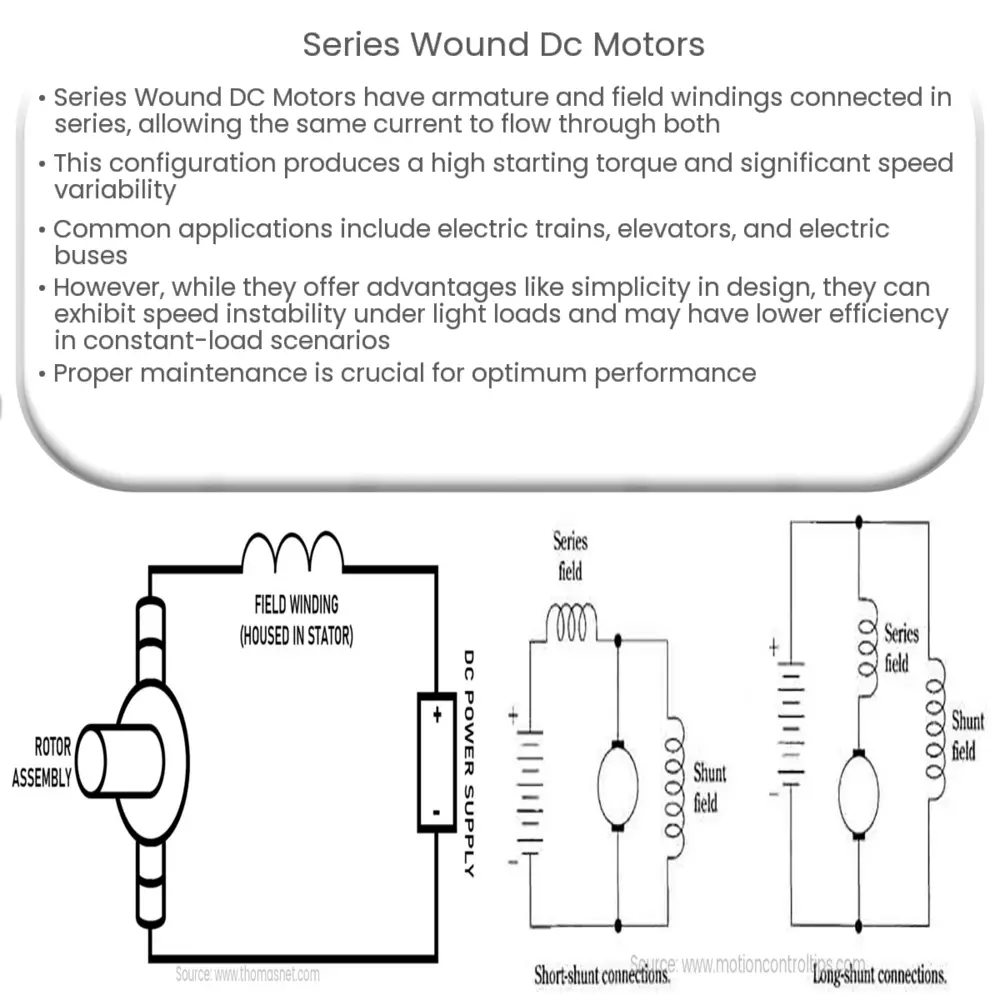

A typical Series Wound DC Motor comprises two primary components:

- Armature: Also known as the rotor, the armature is the rotating part of the motor, made up of windings or coils mounted on a metal core.

- Field Windings: These are the stationary part of the motor, made up of large coils of wire that create a magnetic field when current flows through them.

The armature and field windings are connected in a series, meaning the same current passes through both, resulting in a strong magnetic field. This strong field allows the motor to generate a significant amount of torque, even at low speed.

Working Principle of Series Wound DC Motors

The working principle of a Series Wound DC Motor is based on the fundamental law of electromagnetism known as Faraday’s Law of Electromagnetic Induction. When the motor is supplied with DC voltage, current flows through the armature and field windings. This current creates a magnetic field which interacts with the field produced by the field windings, causing the armature to rotate. As the speed of rotation (N) is inversely proportional to the total flux (Φ), when the load on the motor increases, the speed decreases and vice versa. This relationship is usually denoted as N∝1/Φtotal.

Applications of Series Wound DC Motors

Due to the specific characteristics of high starting torque and speed variability, Series Wound DC Motors are often used in applications that require significant power for a short duration. Examples of such applications include:

- Electric Trains

- Cranes and Hoists

- Elevators

- Electric Buses

Advantages and Disadvantages of Series Wound DC Motors

Like any piece of technology, Series Wound DC Motors have their advantages and disadvantages, which can influence their suitability for various applications.

Advantages

- High Starting Torque: Series wound DC motors are known for their ability to provide a high starting torque, which is useful in applications like electric trains and elevators, which require strong initial force.

- Simple Design: The simple construction of these motors makes them easy to manufacture and repair. This simplicity extends to their operation and control as well.

- Speed Variation: Due to the series connection of the armature and field winding, the speed of the motor varies significantly with the load, making it ideal for specific applications.

Disadvantages

- Speed Instability: Under light loads, these motors can attain dangerously high speeds. This makes them unsuitable for applications requiring consistent speed, regardless of the load.

- Poor Efficiency: When used for constant-load applications, Series Wound DC Motors tend to have lower efficiency compared to other types of DC motors.

Understanding the Importance of Proper Maintenance

While Series Wound DC Motors have inherent advantages that make them suitable for certain applications, their performance and lifespan are largely dependent on proper maintenance. Regular checks and services can help prevent common issues such as overheating, worn-out brushes, and bearing failures. Additionally, periodic inspection of windings for signs of damage or corrosion can help prolong the life of the motor and maintain its efficiency.

Conclusion

In conclusion, Series Wound DC Motors offer a unique blend of characteristics making them a vital component in various industries. Their high starting torque, speed variability, and simple design are balanced by a few disadvantages, such as potential speed instability and lower efficiency under constant loads. With proper understanding and maintenance, these motors can serve a wide range of applications effectively, solidifying their place in the world of electromechanical systems.

Remember, choosing the right motor depends on the specific requirements of your application. Therefore, it’s essential to have a clear understanding of the workings and characteristics of different types of motors, including the Series Wound DC Motor.